C-1.1 Types of Fixtures and Trim

Plumbing fixtures, such as bathtubs, sinks and water closets, are manufactured from a variety of materials and made to suit different operating demands and personal tastes. The hardware and fittings used to install and complete fixtures are called trim. The fixture trim is made from various material combinations to ensure durability and an appealing appearance. Faucets, drain fittings, shower heads, and chrome finish are all examples of fixture trim (Figure 1). The materials used to manufacture fixtures and trim will determine the final properties and cost of each component.

Fixture Materials

The following information on materials is only intended to provide a general description of common materials used to make fixtures and trim. Each manufacturer uses different substances and alloys to produce unique products. For specific information on plumbing materials, consult specification sheets and other literature provided by each manufacturer.

Fixtures and trim can be made from a wide range of materials but must be resistant to corrosion issues caused by constant contact with water. National and provincial plumbing codes require that every fixture has a hard, corrosion-resistant surface that can be kept clean and sanitary.

Fixtures are often made from materials such as porcelain, cast iron, steel, stainless steel, fiberglass and various plastic composites. Trim can be made from combinations of chrome, cast brass, acrylics, and plastics.

Some older installations that use wood in fixtures, such as water-closet tanks, are still in use today. While no longer approved for new installation, these materials may still be encountered in the field. Often, you may need to replace these older plumbing items when servicing because replacement parts are limited, and repair can be difficult.

Vitrified Porcelain

The porcelain used to make plumbing fixtures is a mixture of kaolin, quartz, feldspar, and silica. Kaolin, a fine clay, is used to create delicate porcelain dishes, while silica, a crystalline substance, is found in quartz and glass. The porcelain mixture is poured into moulds and allowed to dry. After being coated with a liquid glaze, it is vitrified to give it a stain-resistant glass-like finish.

Vitrification is a process in which the porcelain and glaze are heated to a very high temperature, up to 1,400°C (2,600°F), then cooled rapidly.

Vitrified porcelain is also known as vitreous china and is commonly used to make items such as water-closet bowls, lavatory basins (Figure 2), and urinals. Vitrified fixtures have high strength and are resistant to chemicals. Although sanitary and easy to clean, vitrified porcelain fixtures are brittle.

Coated Steel or Cast Iron

Steel coated with porcelain enamel is used to make inexpensive yet strong fixtures, such as bathtubs, basins, and sinks. Steel fixtures are generally manufactured by stamping the fixture shape into a sheet of alloy steel in a high-pressure forming process. It is then coated with enamel (powdered glass), which is usually fused on at temperatures above 750°C (1,400°F).

Grey cast iron is cast (moulded) into fixtures and then coated with enamel. This material is often desired for bathtubs and sinks due to its high density and low noise transmission (Figure 3). Cast iron is strong, durable, and rigid, so it will resist damage from flexing during installation and use. Steel fixtures are generally less durable than cast iron fixtures. Steel fixtures are used less now due to the easy formability and durability of advanced composite materials.

Enamelled fixtures have an attractive, glossy finish. They are sanitary and quite durable if handled carefully during installation. They should not be cleaned with highly abrasive or caustic substances. Enamel prevents the corrosion of ferrous metals and resists mild acids and alkalis.

Stainless Steel

Stainless steel is a durable alloy with a silvery, satin-like finish. Stainless steel differs from carbon steel in that it has the addition of chromium. Chromium produces a passive (rust-resistant) chromium oxide layer that blocks oxygen diffusion to the steel surface. It produces fixtures with a sanitary, easy-to-clean, and chip-resistant surface that does not require additional paint or other surface finishes.

300 series chromium-nickel stainless steel is commonly used for manufacturing kitchen sinks, drinking fountains, and many types of commercial and institutional fixtures. The addition of nickel increases impact resistance and assists in forming the fixtures.

Stainless steel sinks usually range from 16 gauge (thick) to 22 gauge (thinner). Heavier gauges of stainless steel are more resistant to dents and have better sound insulation when washing dishes or operating a garbage disposal.

Copper

Copper is sometimes used for manufacturing items, such as bathtubs, sinks, and basin vessels. Ductile copper is often formed by hand into the desired shape (Figure 4).

Acrylic and Other Plastics

Bathtubs, hot tubs, spa tubs, and some basins are often made from relatively inexpensive acrylic plastic. These products are produced by vacuum-forming sheets of acrylic and then spraying a finishing coat of fibreglass and polyester resin to provide strength (Figure 5).

Acrylic plastic has the advantage of accepting a wide range of dyes in the forming process; the colour goes right through the materials because it is not just sprayed on top. It can be made into fixtures with a marble-like finish in a range of designer colours. It has a high rate of thermal expansion and may split when subjected to very high or very low temperatures.

Polyester Resin and Fibreglass

“Gel-coat” fixtures are made from polyester resin reinforced with fibreglass to add strength and durability. The fixture is coloured by spraying a coat of paint gel onto a waxed mould. Then, resin and pieces of fibreglass are sprayed on, and the product is cured. This process allows polyester resin to be used to make complex shapes or large, one-piece fixtures, such as shower stalls and bathtubs. Polyester resin fixtures can be damaged by abrasives or harsh chemicals, but they are relatively easy to repair.

Natural and Composite Stone

Marble, terrazzo, granite, and other natural and composite stone products are used for vanity basin tops, sinks, bathtubs, and shower bases (Figure 6). Some fixtures can also be formed from concrete or terrazzo. Terrazzo is a composite material that consists of marble, quartz, granite, and glass mixed with a binder and poured in place or precast.

Trim Materials

Trim can be made from a wide range of materials. Faucets can be made from brass combined with chrome, zinc, copper, plastic, or china. Cast brass and acrylic plastic are the most common base materials used for supply and waste trim. Specialized trim components can be made of hardwoods, stone, or even plated with gold.

Cast Brass

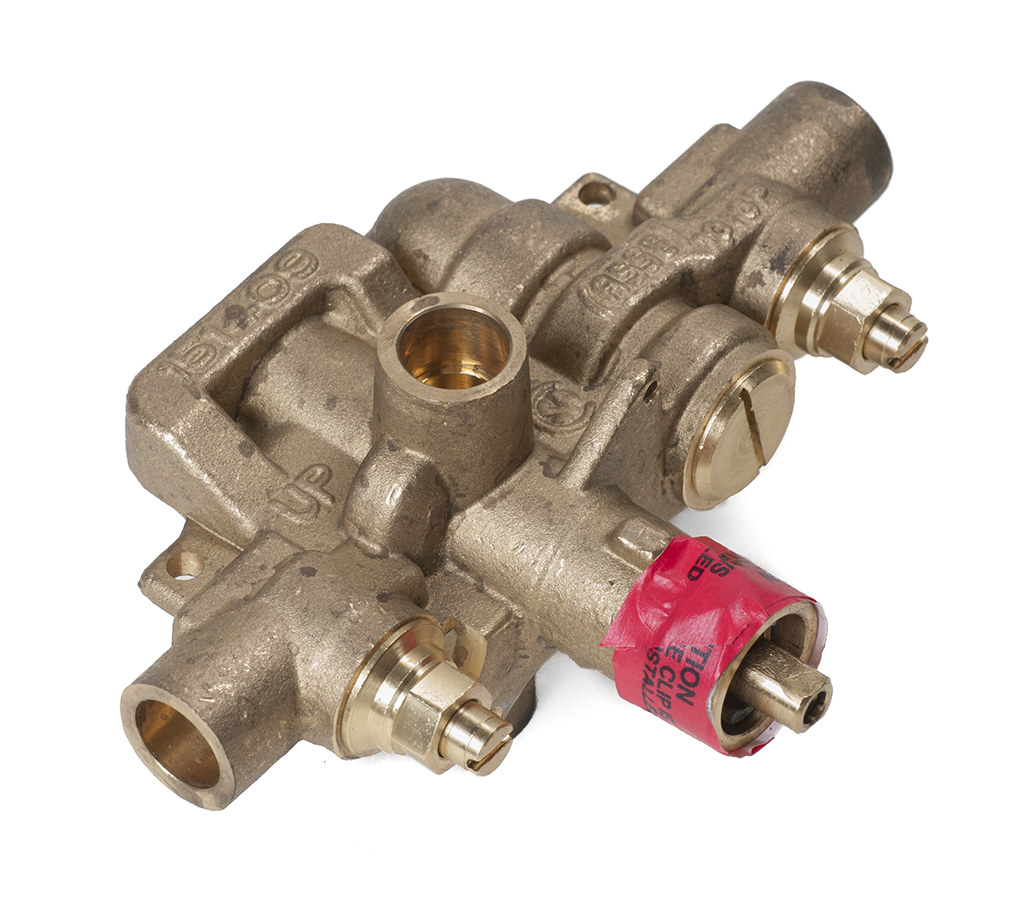

Brass is an alloy of copper and zinc used to make the internal or unseen components of trim. Visible parts and accessories are generally chrome-plated to provide a more attractive, easily cleaned surface. Less-expensive finishes are obtained by using polished brass or rough nickel-plating (known as brushed nickel). High-end finishes may use polished or brushed gold plating.

Valves are usually made of brass because it is highly resistant to the corrosive effects of hot and cold water. Cast brass is used to make shower heads, faucet valves, spouts, and other working components (Figure 7). Nickel and chrome can be scratched or dulled by chemicals, such as ammonia. Brass fittings manufactured for use in potable water plumbing systems are required to be lead-free. The existing lead-free standard requires that the maximum lead content of the wetted surfaces of plumbing products, such as pipes, pipe fittings, plumbing fittings and fixtures, be a weighted average of 0.25% or less.

Acrylic Plastic

Plastics are inexpensive, waterproof, and easily formed. Acrylic plastic is available in an endless array of colours and also used to make trim handles, toilet seats, and decorative covers.

Basic Fixture Types

Some plumbing fixtures are common to single-family dwellings, multi-unit developments, commercial, and industrial settings. There are many unique fixtures now available on the world market, but this competency will primarily discuss the most commonly available fixtures.

You may encounter some older fixtures discussed here when performing plumbing service in the field.

Fixtures are regulated by nationally developed (CSA or equivalent) standards. These standards specify the material, design, performance, and testing requirements. Most manufacturers of plumbing fixtures have their products certified by a third-party testing lab to prove conformance to the applicable standard. In Canada, fixtures must meet the requirements of the CSA B45 series of standards.

Fixtures installed in certain occupancies may also need to meet specific accessibility requirements. The basic plumbing fixtures used in most plumbing systems are:

- Water closets (toilets)

- Urinals

- Lavatories

- Drinking fountains

- Sinks

- Bathtubs

- Showers

- Bidets

- Floor drains

- Interceptors

- Hospital and institutional fixtures

- Emergency fixtures

Water Closets (Toilets)

The ancient Greek civilization of Crete, known as the Minoan civilization, was the first civilization to use underground clay pipes for sanitation and water supply. Their capital, Knossos, had a well-organized water system for delivering clean water, removing sewage, and using storm canals to accept overflow during heavy rain. The Minoans introduced one of the first uses of a flush toilet, dating back to the 18th century BC.

Modern water closet designs reflect the manufacturers’ response to the demands of different installations, advances in technology, and ever-growing concerns with water conservation. Common materials in the construction of water closets are porcelain, stainless steel, and reinforced plastic. Vitrified water-closet bowls are cast in several pieces that are assembled into one unit prior to being fired in a kiln.

The two most common water-closet mounting patterns are floor-mounted (with either bottom outlet or back outlet) and wall-mounted (back outlet). Within these two categories, toilets are also available with round-front bowls or elongated bowls. National and provincial plumbing codes require that water closets installed in public washrooms be of the elongated type.

The closet tank may be a separate unit attached to the bowl, called close-coupled (Figure 8), separately wall-mounted (Figure 9), or a unibody design, where the tank is cast as part of the overall water-closet fixture. Tankless water closets (called direct flush) have a direct connection to a high-volume water supply for the flushing action (Figure 10).

Historically, water-closet tanks were mounted high above the bowl (Figure 9). This assisted in creating head pressure to flush the fixture. A chain allows the user to activate the flush valve in the tank. The tank and bowl are connected via a flush pipe and flush elbow that direct water from the tank down toward the bowl.

Floor-mounted water closets with closet tanks (called flush tanks) and bottom outlets are usually found in private residences and office washrooms. Floor-mounted toilets with back outlets are useful in areas that have very little space underneath the floor. They allow the drainage piping to be connected horizontally above the floor. Wall-mounted and floor-mounted toilets may be activated by a flush tank or a direct-flush valve (also known as flushometer valves). Direct-flush valves are a “tankless” design that uses water pressure from the supply line rather than a tank of water to flush the fixture (Figure 10).

Wall-mounted fixtures require additional support to avoid transmitting any weight to the wall finish. They are usually supported by a concealed fitting, called a carrier, mounted between the studs in the wall or to the floor below. Wall-mounted designs are popular in commercial and industrial installations because they allow for a more thorough cleaning of the floor around and underneath the fixture. Water closets with direct-flush valves and elongated bowls are the type often used in commercial and institutional buildings.

Water Usage

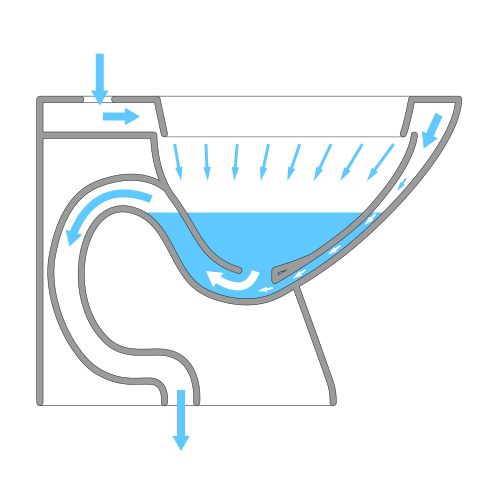

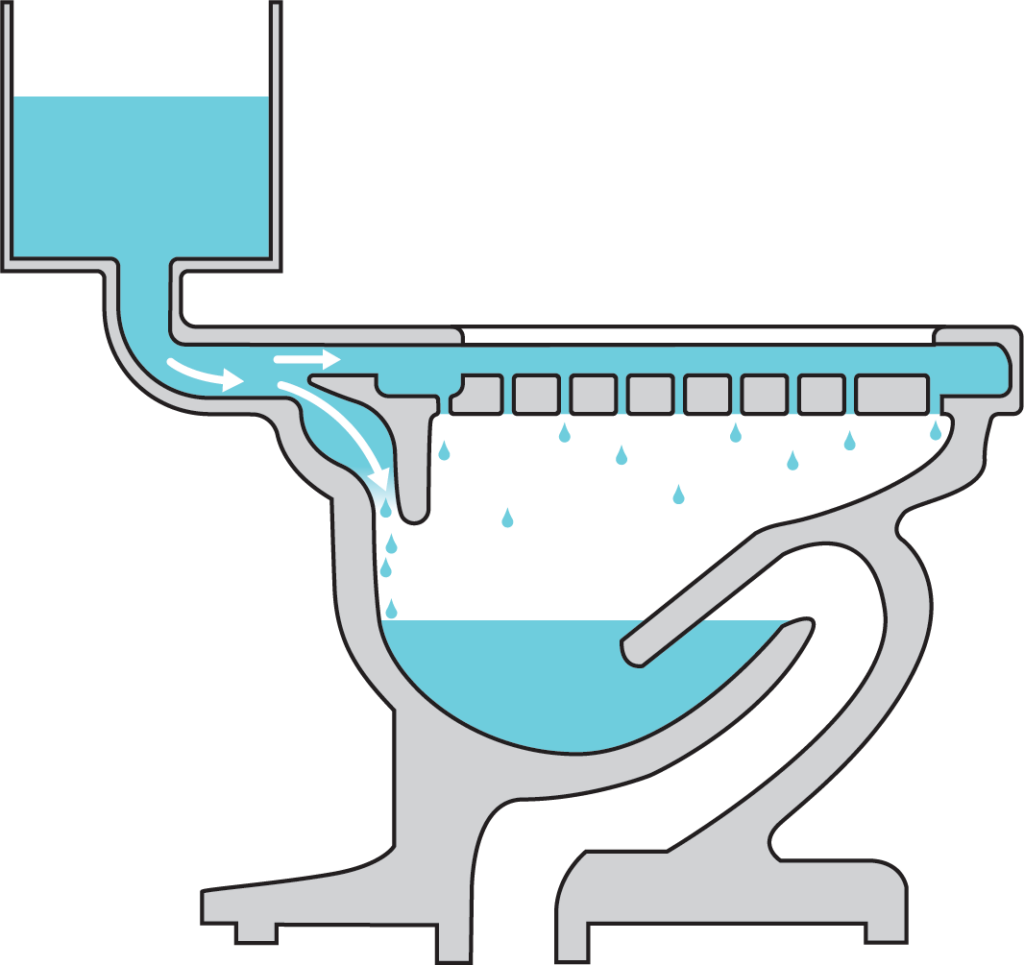

Modern toilets use jets of water near the trapway and/or from holes around the inner rim of the bowl. This, coupled with the partial vacuum created by the trapway design, empties the contents of the bowl.

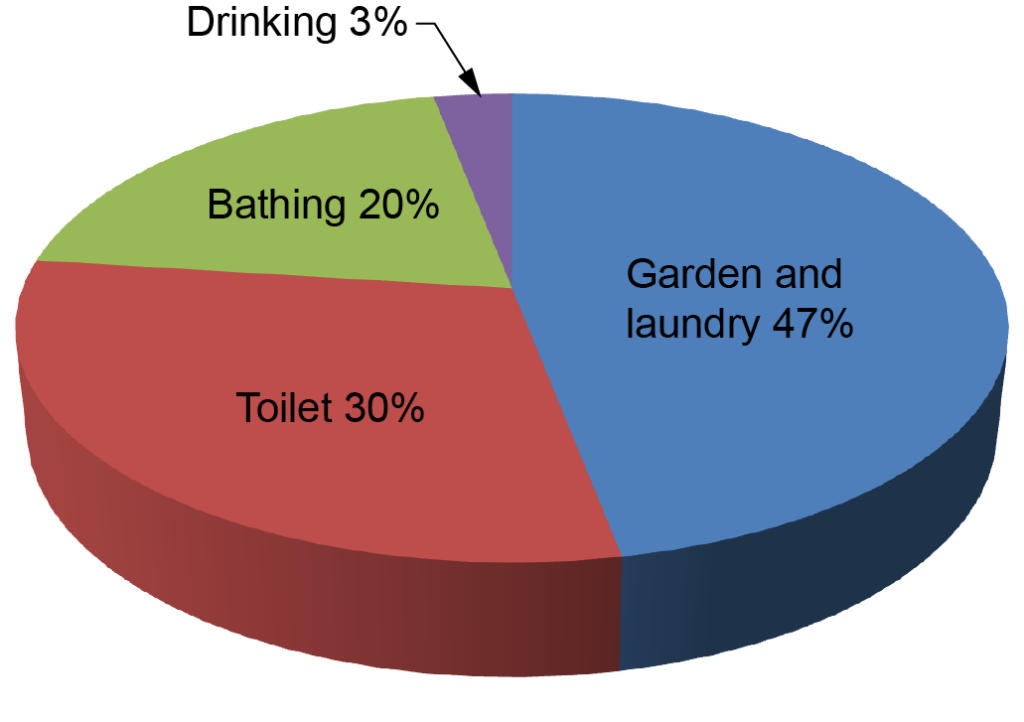

Toilet flushing is the single highest use of water in an average home (approximately 30%, Figure 11) and presents a prime opportunity for water conservation. As such, regulations have had a profound influence on the design of water closets. Older units can discharge as many as 13–20 L (3–4.5 imperial gal.) of water on each flush cycle, which contributes to a tremendous amount of potable water being used to dispose of waste.

An average family of four people using an older water closet (13 L/3 gal.) will use approximately 98,000 L (21,500 gal.) of water per year, while the same family using an ultra-low flush (ULF, 6 L/1.3 gal.) would use only about 45,000 L (9,900 gal.) per year. High-efficiency toilets(HET) can use even less water (4.8 L/1 gal. or less). Dual-flush toilets have full flush and “half-flush” capabilities. These measures save more than half of the water needed to flush the fixture and equally reduce what is discharged to the sanitary waste system, which typically requires significant treatment. This provides a double financial benefit for most regional jurisdictions and a tremendous reduction in impact on the environment.

In terms of water consumption, dual-flush toilets are classified as HETs because the ratio of reduced flushes (up to 4.1 L/0.9 gal.) to full flushes (up to 6 L/1.3 gal.) results in an effective flush volume that is less than 4.8 L (1 gal.).

Effective since 2010, HETs or dual-flush toilets are required in new residential buildings in BC (or when major renovations occur). The requirement for toilets with a maximum flush cycle of 6 L (1.3 gal.) in industrial, commercial, and institutional buildings remains unchanged.

Many new buildings use alternative means to flush water closets (Figure 12). Means of using captured rainwater, waste condensate, reclaimed water (such as grey water or process water), or even seawater are most practical to install during new design and construction.

The design used to evacuate waste and water from the closet bowl varies. The most widely used designs are:

- Siphon jet

- Reverse trap

- Blowout

- Washdown

Other types of unique toilet fixtures are common in some parts of the world (e.g., squat toilets and various types of dry toilets). They may be found in certain places locally as well, but their relevance is limited for a Canadian plumbing apprentice.

Siphon Jet

Standard siphon jet water closets function by evacuating the contents of the bowl with jets of water combined with a siphoning action (Figure 13). When water flows from the tank though the rim jets, standing water in the bowl rises, filling the elongated S-shaped siphon waterway. This starts the toilet’s siphonic action, pulling nearly all of the water and waste down the drain. When most of the water is drained out of the bowl, the siphon is broken, and you may hear its characteristic gurgle at the end of the flush. There may also be an additional jet about 2.5 cm at the bottom of the bowl to create more flushing inertia.

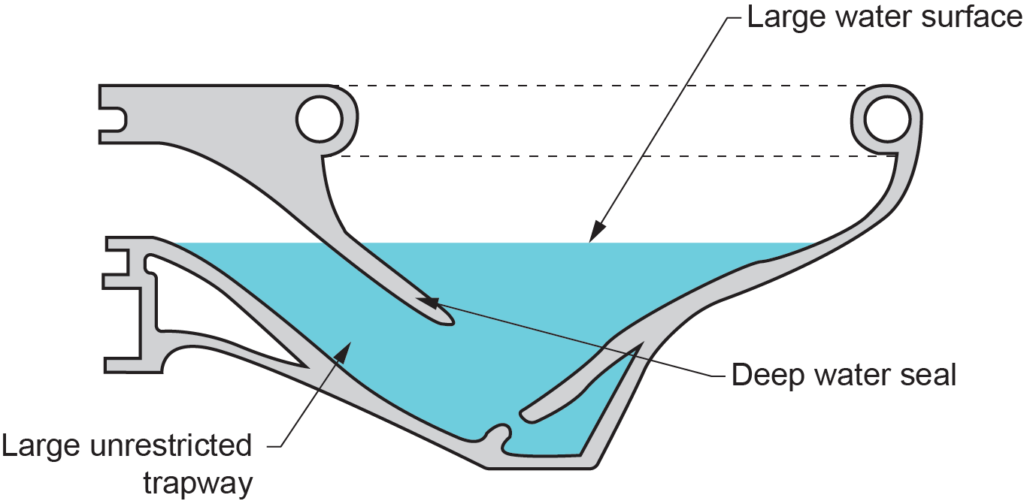

The trapway is a moulded passage that carries waste and water from the bowl into the outlet. The trapway’s highest point (called the weir) maintains a minimum level of water in the bowl, creating a seal so that no sewer gases can enter the dwelling.

Siphon jet water closets have a large water surface and deep seal depth, which assist in keeping the bowl clean. The trapway is typically a minimum of 5 cm (2 in.) in diameter. For these reasons, siphon jets require larger volumes of water to effectively operate.

Vacuum-Assist

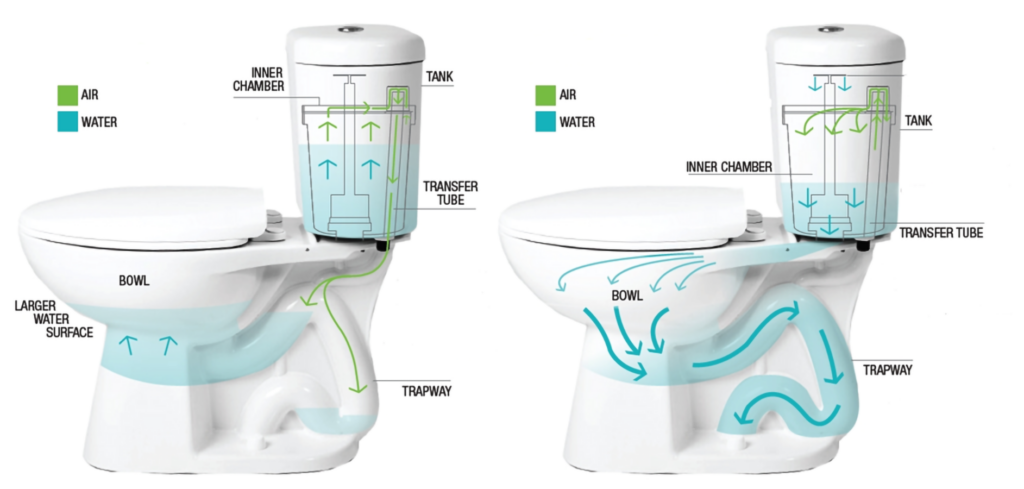

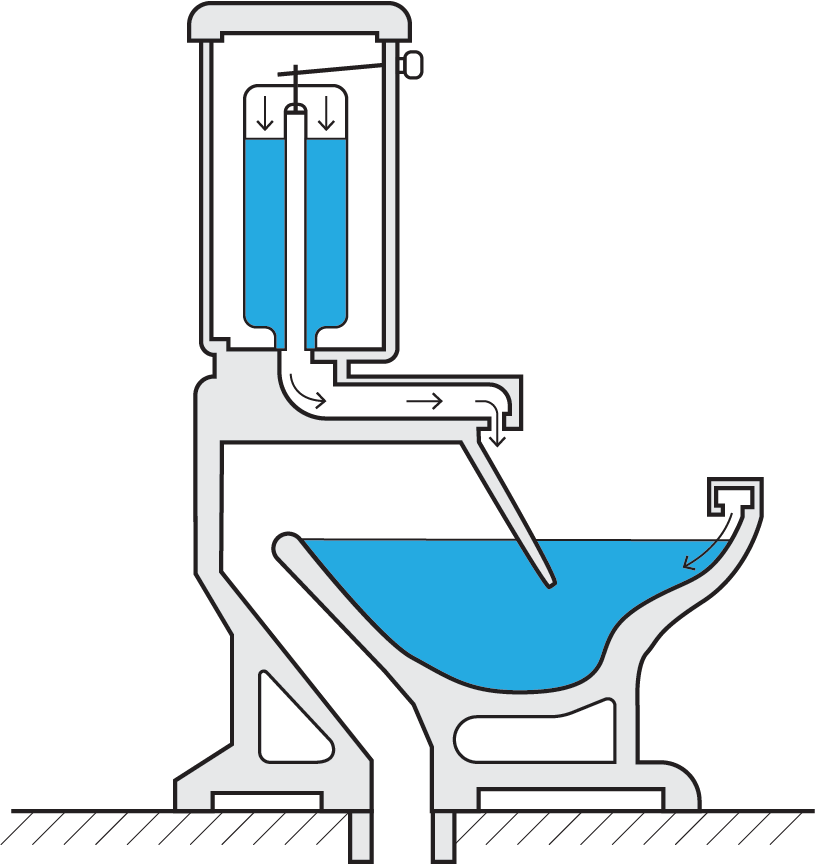

Vacuum-assist toilets use passive vacuum system to create a HET, with the large surface area characteristic of a conventional siphon jet design. After the toilet is flushed (Figure 14a), water fills a special chamber inside of the tank.

As the inner chamber fills, air at the top is pushed down the transfer tube into the trapway, creating an air bubble between the water in the toilet bowl and water in the lower trap near the base of the toilet. This air bubble exerts a force on the water in the trapway, raising the water level in the toilet bowl and increasing the water surface area. When the toilet is flushed (Figure 14b), water exits the lower trap, pressurizing the trapway pulling the wastewater in and initiating the siphonic action.

Reverse Trap

The name reverse trap was originally given to any style of water closet that had a trapway that discharged toward the back of the closet bowl. This was the “reverse” direction of how the earliest washdown-style toilet trapways were configured.

The modern reverse trap bowl (Figure 15) is a design developed in response to water conservation concerns. The reverse trap functions in the same way as the siphon jet, but the trapway is smaller (usually less than 5 cm/2 in. diameter) and there is less surface area of water in the bowl. Therefore, less water is required for flushing and operation.

Pressure-Assist

Pressure-assist water closets (Figure 16) differ from a standard gravity flush toilet in that they use the addition of compressed air to assist the flush action. As water refills the tank, a captive vessel holds a volume of air compressed by the incoming water flow. Although pressure-assist toilets may be less desirable due to their loader flush, they may be a solution for locations prone to clogging issues. They are popular in public restrooms, where a blowout water closet may not prove practical because of water supply pressure limitations.

Blowout

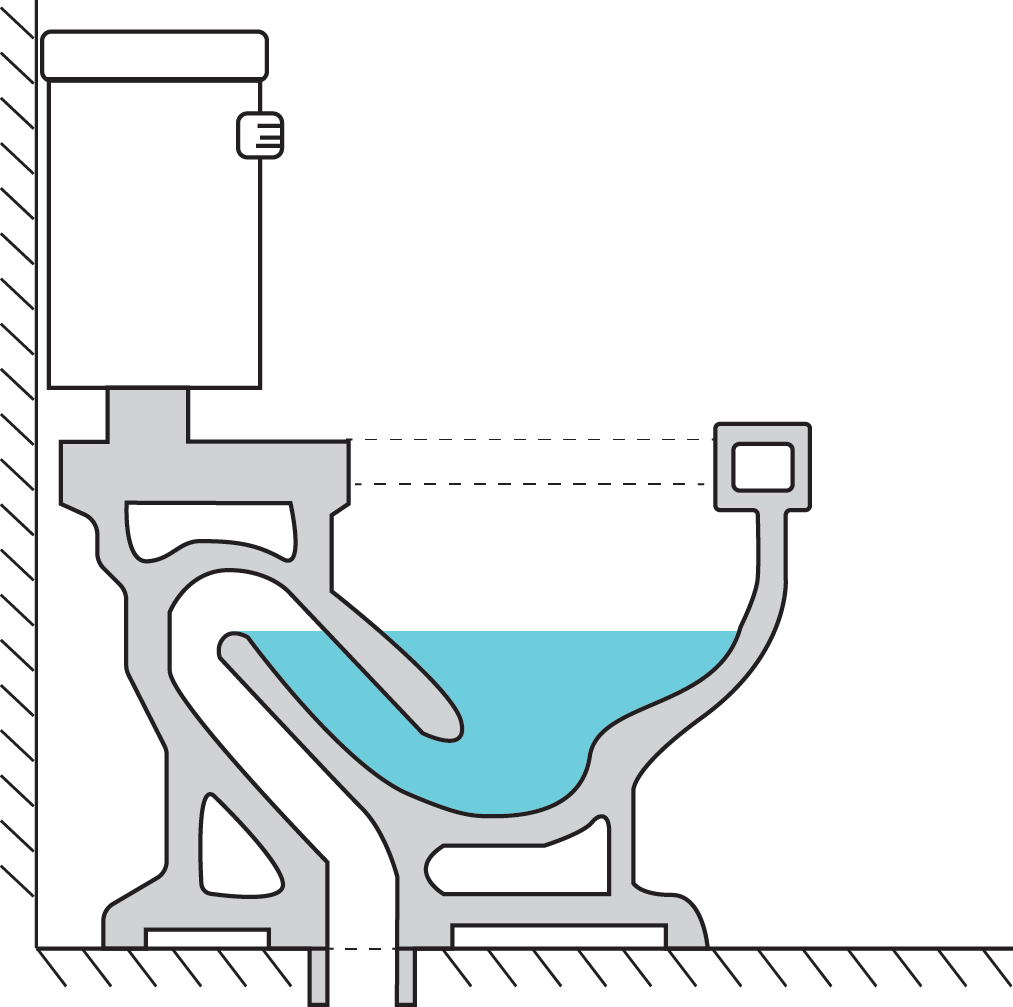

A blowout bowl is generally installed in a wall-hung configuration (Figure 17). Blowout bowls have a very large water surface area and a deep water seal. The unrestricted trapway depends upon a large-volume jet of water to initiate the flushing action because the bowl lacks the articulated S-trap design common to most bowl types. Therefore, a direct-flush valve using a minimum 1 in. nominal size supply pipe is used to flush these types of bowls.

Wall mounting this fixture requires a considerable carrier support structure concealed in the wall cavity. Due to their significant mounting requirements, the large water supply needed, and substantial noise during operation, blowout water closets are not a common residential fixture.

Washdown

Washdown water closets (Figure 18) are the earliest design of flushing toilet. Although no longer manufactured, some installations still exist. These water closets have a waste outlet located at the front of the bowl that is trapped below the water seal. The front passageway is situated above the water line and thus is more subject to staining and fouling.

Although technically a trap, the outlet passageway is a much simpler design than a siphon trapway, and suction is not developed to aid the removal of waste. Washdown water closets rely on only water head pressure to empty the bowl, and the water typically must rise to an alarmingly high level before the contents are removed.

Urinals

Urinals are typically installed in men’s public washrooms (although women’s urinals are also manufactured). They are designed to receive only urine directly. Urinals are made from vitreous china or stainless steel.

There are two main types of urinals:

- Stall urinals

- Wall-hung urinals

Stall urinals (Figure 19) are not named such because they are located in stalls. In fact, more often than not, they are not equipped with dividing walls. Stall urinals are a washdown-style urinal, are floor-mounted, and have their drain outlet located near the user’s feet. The trap is located below the finished floor level, and the urinal is flushed only by a gravity flow of water along the inner walls of the fixture. One or more stall urinals may be flushed by a flush tank, or individual units may be flushed by a flush or metering valve. Regardless of the method, the water supplied to the fixture enters slowly, and the trapway is not completely emptied on each cycle. This leads to generally unpleasant conditions. Cleaning the outlet and fixture drain is difficult, and the low lip level leads to frequent trash accumulation.

If a stall urinal is damaged after installation, removal and replacement are very costly and time consuming.

Wall-hung urinals (Figure 20) differ based on flushing style. Some types are fed with water from a gravity-assisted flush tank, while others may be fed water via a metering or direct-flush valve. Water-free urinals are also increasingly installed where water conservation is vital.

Wall-hung urinals are supported by carriers or wall brackets. The height at which they are installed depends on the height of the intended user and is based on project specifications.

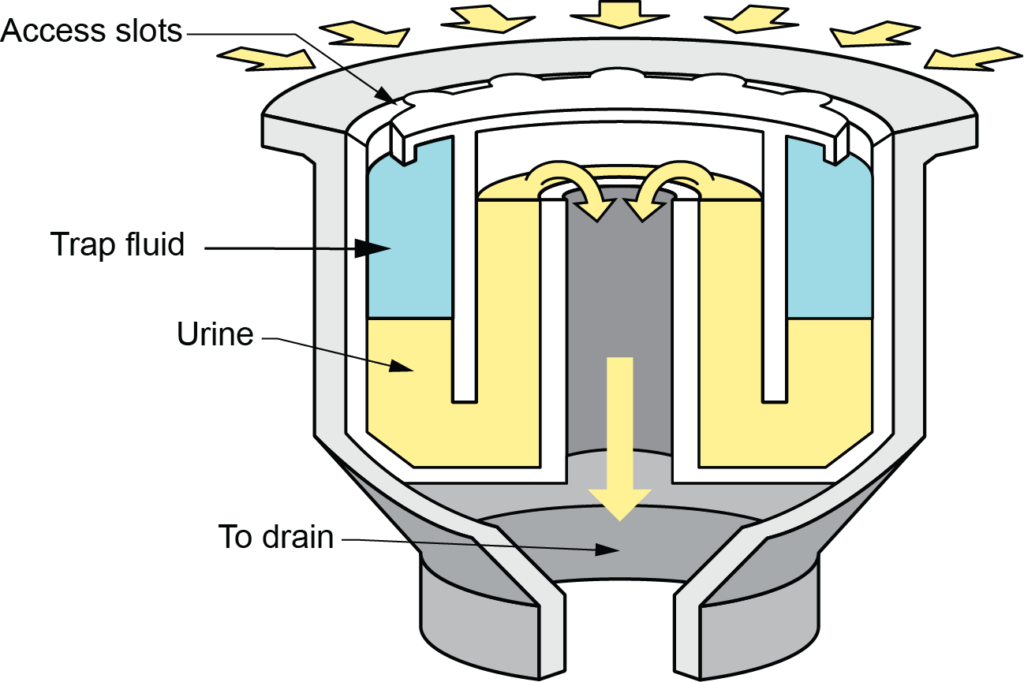

Water-less urinals use a special cartridge in the drain outlet to trap sewer gases and prevent them from entering the room (Figure 21). Undiluted urine is collected from some systems for its value as a high nitrogen- and phosphorus-based fertilizer.

Urinal Flushing

There are several methods of urinal flushing:

- Washdown

- Automatic flush

- Siphon jet

- High-efficiency

Washdown urinals have a water connection at the top of the fixture from which water slowly flows to wash the inside surfaces of the urinal. Waste is washed out of the urinal rather than flushed out. They are usually flushed by a [latex]\tfrac{1}{2}[/latex] in. (13 mm) self-closing metering valve or from a flush tank. Washdown styles of urinals may have a trap located externally below the fixture or integral to the fixture.

Automatic urinal flush tanks (Figure 22) are seldom installed anymore due to their tendency to consume large amounts of water. These tanks fill slowly through a constant trickle of water and discharge automatically when full. To conserve water, building codes now require that urinal tanks be controlled to limit their operation to the hours when the building is normally occupied.

Siphon jet urinals are a style of wall-hung urinal that typically have a jetted, integral trapway that flushes similar to a siphon jet water closet, where the water in the trapway is completely replaced on each flush. The more rapid flushing action of a siphon jet urinal is accomplished by installing a [latex]\tfrac{3}{4}[/latex] in. (19 mm) direct-flush valve.

A high-efficiency urinal (HEU) is a fixture with a flush volume of 1.9 L (0.4 gal.) or less. HEUs use approximately one-third of the amount of water used to flush the average urinal. Based on typical usage, a single HEU can save close to 18,000 L (3,900 gal.) of water per year.

Urinals installed in new buildings and during major renovations in BC are required to be high-efficiency (1.9 L/0.4 gal.) urinals.

Trough Urinals

Trough urinals are meant for use by several people at one time. The trough is either wall-mounted or installed at floor level. They are typically made from stainless steel (Figure 23), enamelled cast-iron, or site-built from tile or stone. Some trough urinals can be found in older buildings like arenas or at fair grounds. They have no dividing walls and offer no privacy to the user. Trough urinals are no longer permitted to be installed in new construction.

Lavatories

Lavatories (also known as basins) are one of the most common fixtures found in homes and public buildings. Lavatories should not be confused with sinks; their primary purpose is to allow people to wash their hands and faces (sinks are used to wash food, dishes and other items).

Lavatories are made of vitreous china, enamelled cast iron, steel, copper, stainless steel, stone or plastic.

Lavatories often have a concealed overflow, which is an overflow drain opening that connects to the waste outlet via an assembly called a patent overflow (PO).

Lavatories are available in three basic styles:

- Wall-hung

- Vanity (or countertop)

- Pedestal

The wall-hung lavatory (Figure 24) may often be found in offices, schools, or other public buildings. This style may also be found in residential installations that may require free access for persons in wheelchairs. The wall-hung lavatory has no legs or external frame for support; it is entirely supported by a wall-mounted bracket or sometimes by a metal carrier located behind the wall finish.

Wall-hung lavatories are available in a wide range of shapes. They may be designed to be mounted in a corner to save space or occasionally with a false centre leg that hides piping and valves, known as a pedestal basin (Figure 25).

Countertop lavatories (Figure 26), also known as vanity basins, are designed to be partially supported by a frame, which may have an enclosed cabinet underneath it (vanity). This style of lavatory is found mainly in private homes. Most modern countertop lavatories are self-rimming so that the old metal finishing rings are no longer required. Self-rimming styles must be carefully measured so that they slip easily into the precut hole in the countertop.

Hair salons use lavatories specially designed for washing people’s hair. Commonly referred to as a shampoo basin (Figure 27), they are similar in construction to a standard lavatory but have a recess for the user’s neck to rest and a pull-out hose used for washing.

The dental cuspidor (Figure 28) is technically a small basin in which the patient can expectorate saliva during treatment. Cuspidors have a water supply, vacuum, and compressed air for providing patient care at a dental office or clinic.

Sinks

Sinks may be made from stainless steel, enamelled cast iron, porcelain, fibreglass, stone, or plastic. There are various types of sinks:

- Kitchen sinks

- Service sinks

- Laundry sinks

Kitchen Sinks

Stainless steel sinks are the most popular type of kitchen sink and vary depending on finish and gauge of the metal. Stainless steel sinks usually range from 16 gauge (thick) to 22 gauge (thinner) and are mastic coated beneath to insulate sound transfer.

Kitchen sinks may have one to three flat-bottomed compartments and varying depths. Some have deep compartments for washing dishes and much smaller, shallower compartment for rinsing vegetables (Figure 29).

Styles are available with or without holes to mount the faucet and accessories, such as a sprayer or soap dispenser.Kitchen sinks are prohibited from having concealed overflows, as they would trap food and organic waste. One method commonly used to prevent overflows in multi-compartment sinks is to build a slightly lower integral weir into the ledge separating the compartments.

Service Sinks

Also known as mop sinks, service sinks are wall- or floor-mounted sinks found in commercial and industrial settings or medical facilities. They are generally made of stainless steel, enamelled cast iron, stone, or plastic. They are typically installed in conjunction with janitor’s faucets, with hose attachments to fill buckets quickly. The front lip of a wall-mounted service sink has a metal rim to protect the enamel from being damaged by buckets and other cleaning equipment.

Figure 30 shows a cast iron P-trap standard equipped with a cleanout. These are commonly used for a wall-mounted service sink. The trapway is typically a minimum of 3 in. to permit the quick discharge of wash buckets.

Laundry Sinks

Also known as laundry trays (Figure 31), these are a common fixture in older residences. Made of concrete, stone, stainless steel, or plastic, they were used for hand washing clothing before automatic washers were adopted. Later, they proved to be convenient locations to indirectly drain the auto washer’s discharge hose if a separate standpipe was not available. In newer homes, a laundry tray is a useful utility fixture for prespraying or soaking laundry, as well as for washing various other goods.

Drinking Fountains

Drinking fountains are made from vitreous china or stainless steel. Commonly found in schools, public buildings, commercial enterprises, and factories or mills, drinking fountains provide easy public access to potable water. When located inside buildings, they are either wall-mounted (Figure 32), freestanding, or recessed into a wall. They often include a built-in bottle refill station.

The recessed model is preferred in high-traffic areas or where little space is available. Outdoor fountains, located in parks or green spaces, may be installed in durable, freestanding decorative bases or mounted on the outside of a structure. Some parks even have water fountains for dogs.

Bathtubs

Bathtubs are usually made of enamelled steel, enamelled cast iron, copper, or fibreglass-reinforced acrylic. Bathtubs may be designed to be fully recessed into a wall, set as a skirted or corner design, placed within a built-in structure, or freestanding.

Full surrounds are available for installation in conjunction with recessed tubs to provide a complete showering unit (Figure 33).

In the latter half of the 20th century, the once-popular freestanding clawfoot tub (Figure 34) morphed into the recessed tub with a small apron front. This enclosed style afforded easier maintenance and, with the emergence of coloured fixtures, more design options for the homeowner. The Crane Company introduced coloured bathroom fixtures to the North American market in 1928.

The front of the tub, the side not touching a wall, is often referred to as the skirt or apron. Bathtubs have drains located on the left side or right side, as determined by facing the apron or opening to the tub. For example, if the drain is located to the left when facing the apron, it is considered a left-hand tub.Bathtub drains have overflows piped to the outlet of the tub prior to installation. The waste and overflow arrangement drains the tub to a trap located below the floor.Whirlpool tubs (Figure 35) first became popular in North America during the 1960s. A whirlpool tub (also known as hydrotherapy, jetted, or spa tub) is essentially an indoor hot tub and is sometimes still referred to simply as a “Jacuzzi” since the word has become somewhat generic after the Italian/American plumbing manufacturer Jacuzzi introduced the home spa whirlpool in 1968.Air bubbles are commonly introduced into the whirlpool tub nozzles as a 50/50 mixture of air and water through a venture-style pump.

Showers

Shower stalls separate from bathtubs can be either freestanding or built into wall recesses or corners. The walls may be made from glazed tiles, stone, fibreglass-acrylic, or any waterproof material. Shower stalls can be supplied with one-piece moulded walls or separate wall panels bonded together. The base of the shower stall is usually shaped like a squared-off dish (Figure 36) with sides that rise above floor level. The base may be made of cast stone, granite, fibreglass, acrylic, or terrazzo. Shower bases are available in different heights, widths, and depths. Commonly available base sizes are 750 mm by 750 mm (30 in. by 30 in.) and 91 cm by 122 cm (36 in. by 48 in.).

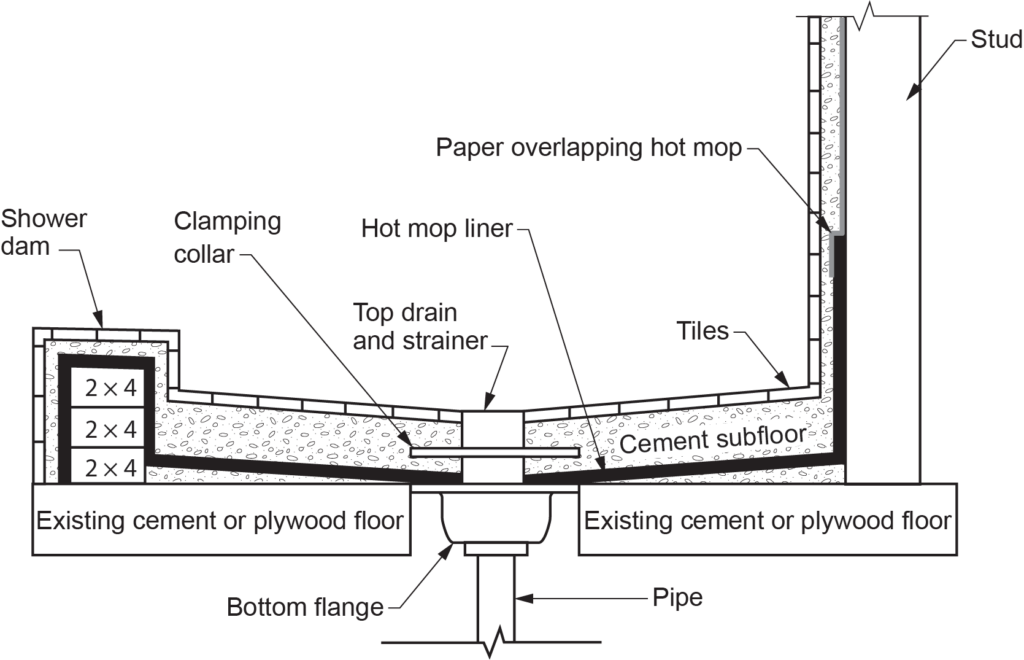

Shower stalls for people with special access requirements do not have a separate base with high sides. Instead, the floor is usually lined and sloped (more than the standard 1:50 or [latex]\tfrac{1}{4}[/latex] in. per foot) so that water runs by gravity into a drain inside the shower area. A very slight lip extends around the perimeter or side and provides some additional overflow protection without interfering with ease of access. These types of shower stalls are generally designed larger than standard shower stalls.Site-built shower bases (Figure 37) are constructed in one of several methods. They can be made by creating a waterproof membrane of hot tar and tar paper (Hot Mop) laid upon contoured dry pack mortar or manufactured preformed liners. The clamping collar is tightened down to the the liner to create a seal. Weep holes (not shown) allow water above the liner, which seeps down through the grout to flow into the drain. Site-built shower walls are often constructed from tile on concrete wall board.

Bidets

Bidets (Figure 38) are fixtures widely used in Europe and Latin American countries but are not as common in North America. Designed primarily for washing the genital areas, bidets provide an extra level of personal cleanliness.

Similar in appearance to a water closet with the functions of a lavatory, a bidet is only designed for clear-water waste. It has hot and cold water control valves, a spout, a drain outlet, and usually some form of integral water jets. The jets are formed as water is forced upward through a series of small holes in a raised nozzle.

Floor Drains

A floor drain is a plumbing fixture installed in the floor of a building to accept a flow of water or other liquid. Floor drains are considered either emergency or non-emergency. Emergency floor drains are not intended to receive the discharge of a continuous flow–type fixture; they are designed to protect against flooding in the event of a fixture overflow or a relief valve discharge.

Floor drains are typically 2–4 in. (5–10 cm) in diameter. The floor around the drain is also sloped to allow the water to flow to the drain. Most residential basements have one or more floor drains, usually near the water heater or automatic washer. They can also be found in commercial basements, restrooms, kitchens, refrigerator areas, shower rooms, laundry facilities, and near swimming pools, among other places.

Some floor drains have a strainer secured over them to prevent a tripping hazard and the entry of foreign objects. Some have a funnel or hub over the drain body to provide a neat installation for drainlines indirectly connected to the floor drain (Figure 39).

Interceptors

Interceptors are fixtures installed to intercept unwanted particles or substances before they can enter the downstream drainage system. Various types of interceptors are required by codes and regulations to protect municipal sewer systems. Isolating materials, such as grease, oil and toxic materials, at the source protect both the infrastructure and environment from pollution and contamination. Interceptors are often made of coated steel, reinforced concrete, or plastic.

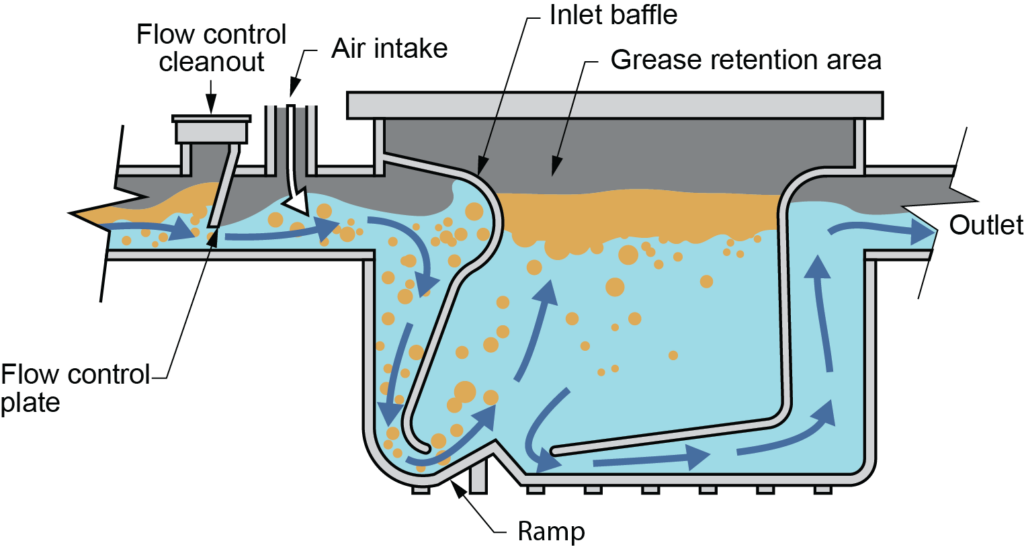

Grease interceptors (Figure 40) are commonly installed in commercial and institutional kitchens or wherever large amounts of fats, oils, or grease (FOG) are expected. Grease interceptors are intended to remove up to 90% of the grease and oils from sink wastewater to prevent clogging of drain piping. Their primary purpose is to slow the flow of FOG and separate it from the liquid waste. Grease interceptors are referred to as grease traps when they are used as the actual trap for a fixture. Grease traps must maintain a minimum 38 mm ([latex]1 \tfrac{1}{2}[/latex] in.) water seal.

Grease interceptors have a series of internal baffles that encourage fats and grease to separate from the wastewater as it cools. A removable cover allows access to clean out accumulations of congealed grease. Flow control devices may also include inlet orifice plates to maintain design flow rates through the unit. Inlet air admittance fittings are used by some manufacturers to add air to the inlet flow and assist in making the FOG more buoyant (Figure 41).

A grease interceptor must be periodically cleaned to remove the contents. The frequency of cleaning depends on the usage factors of the system. Waste FOG is usually recycled at an appropriate facility and can often be used as a source of biofuel.

Food particles and other solids should never be allowed to drain to a grease interceptor because it decreases the interceptor’s effectiveness and increases the requirement for cleaning and maintenance.

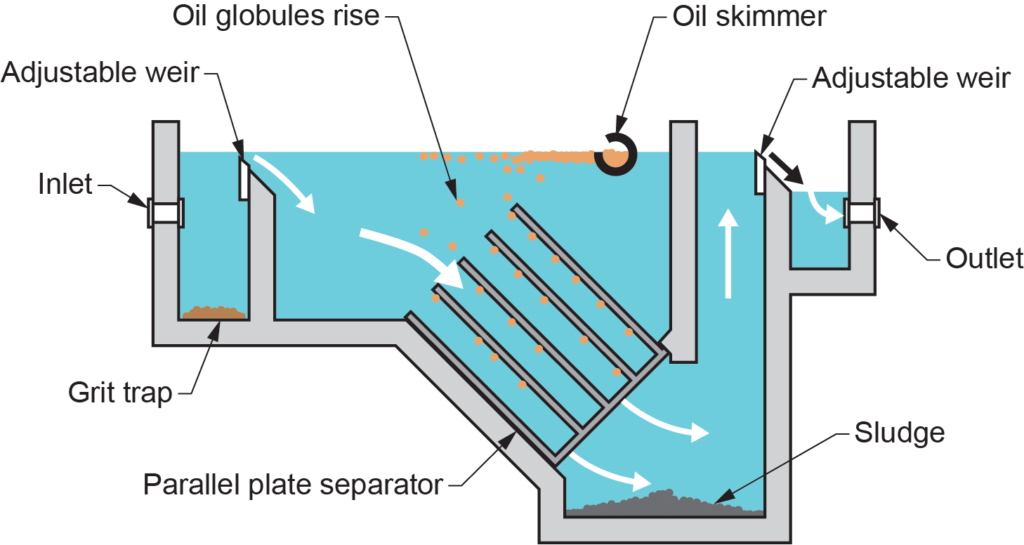

Oil interceptors (Figure 42) are installed at automotive, marine, and similar sites that use heavy motor oils, lubricants, or lubricating grease. An oil interceptor separates oil from wastewater as it flows through wire mesh interceptor panels and baffled chambers. The panels are often made from steel coated with epoxy. A calibrated orifice plate regulates the required flow rate, and removable covers allow the panels to be removed for cleaning.

Industrial and commercial establishments may also use interceptors to remove debris, such as hair, lint, plaster, fish scales, or other sediment. These devices all have similar functions. Perforated baffles or steel mesh baskets, sized for the material being filtered, prevent foreign material from entering the drainage piping (Figure 43).

Hospitals and Institutional Fixtures

Fixtures with special adaptations are found in hospitals, institutions, laboratories, and medical clinics. Sinks and lavatories often have controls that can be operated by knees, arms, feet, or sensors. Because of the need for greater control for the safety of patients, thermostatic control valves are used in many showers and bath fixtures. Toilets, bathtubs, and showers also have grab bars installed in strategic locations.

Barrier-free washrooms have minimum dimensions required for suitable access and use of the fixtures. Many institutions also have specifications for installing fixtures that may exceed minimum code requirements. Always check the fixture specifications very carefully when installing this equipment.

Manual types of bedpan washing equipment use a water supply to a spray attachment. They are essentially a toilet-style wash station that can be used to readily empty, clean, and flush the contents of a patient’s bedpan. The flushing bowl is commonly called a clinic sink and is equipped with a direct-flush valve. Newer hospitals typically employ automatic types of bedpan washing equipment that use chemical and thermal disinfection for improved hygiene.

The sitz bath is typically made of vitreous china or acrylic plastic and looks somewhat like a deep sink with a front face lower than the back. These are used as a method for lower body bathing and soaking for relaxation and therapy.

Combination arm and leg baths are oval-shaped stainless steel tanks with a thermostatic water mixing assembly and an electric turbine ejector. The ejector is equipped with an aerator and an elevator for lowering and raising.

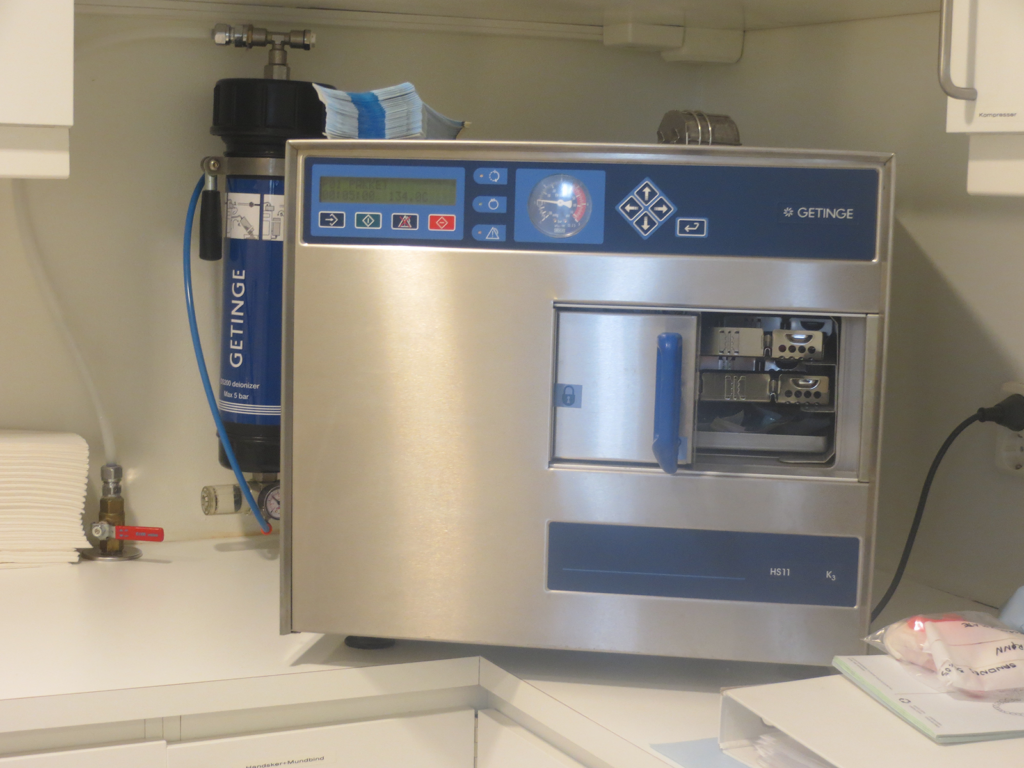

Autoclaves and portable sterilizers are fixtures used to sterilize dressings, instruments, and glassware with moist heat. Moist heat is supplied by boiling water, free-flowing steam, or pressurized steam. High-pressure autoclaves (Figure 44) have air and condensation ejectors that draw air and moisture out of the sealed unit before it is filled with steam. Regardless of the arrangement of valves and safety devices available, all autoclaves have a method of creating a vacuum in the sterilizing chamber to vent steam and a method of drying the contents after the steam cycle is complete.

Portable or installed sterilizers, referred to as sanitizers, submerge instruments or needles in boiling water for a fixed period of time (Figure 45). These fixtures consist of a covered heating container and a heat source to raise the water to boiling point. This method only kills a limited range of bacteria; pathogenic (disease-producing) spore-forming bacteria is only affected by high-pressure steam.

Pedestal-mounted autopsy tables (Figure 45) are heavy-gauge stainless steel fixtures that have large integral sinks, a hot and cold faucet with spray assembly, and some form of hydro aspirator to remove fluids from the cadaver.

Fixtures used in detention occupancies, such as prisons, are made with durability. Stainless steel water closets often incorporate a small, recessed basin above them for washing, while all seams and fasteners remain out of sight to the prisoner (Figure 47). Mechanical systems in prisons are often contained in a chase that houses all required facilities without exposing any wiring, control valves, or other components.

Detox toilets are designed for in-floor installation in holding cells, infirmaries, and correctional institutions. They are designed with a vigorous flushing action and are usually activated by remote means.

Emergency Fixtures

Emergency eyewash stations and emergency showers (Figure 48) are found in laboratories, shops, and industrial locations that have a risk of exposure to chemicals. Users can quickly turn on the water supply to these fixtures by activating large handles or paddles. Some types activate when the user stands on a sensor-equipped platform in front of the station.

Fixture Trim

Fixture trims are available in almost any type of finish desired. Faucet handles and spouts may have rough, brushed-steel finish or be gold plated. Drains and strainers may be stainless steel, yellow brass, or plastic. Other types of trim, such as faucets and water fountain bubblers, are available in a variety of operating designs to suit the needs of different installations, budgets, or personal tastes.

Outlet Fittings

Outlet fittings used in standard sanitary fixtures, such as lavatories, showers and bathtubs, are designed to be flush with the surface of the fixture to prevent dirt and debris from collecting at the rim. Different types of grating designs are available to cover the drain opening. Standard shower stalls have drain outlets located in the centre of the sloped base. A strainer made of chrome, stainless steel, brass, or fibreglass covers the drain opening and minimizes plugging problems. Lavatories, sinks, and water fountains also have drains located in the centre of the fixture. Drains may be open or have built-in strainers. Kitchen sinks have a metal or plastic removable strainer basket that prevents food particles and pieces from entering the drain pipe.

The most common types of tub and basin drain mechanisms are:

- Plug and chain

- Pop-up

- Mechanical stoppers

- Mechanical lever and linkage

Plug and Chain

Lavatories can simply be sealed with a shallow rubber plug that fits into the outlet opening of a patent overflow (PO) outlet tailpiece. The plug is attached by a chain to the faucet spout (Figure 49).

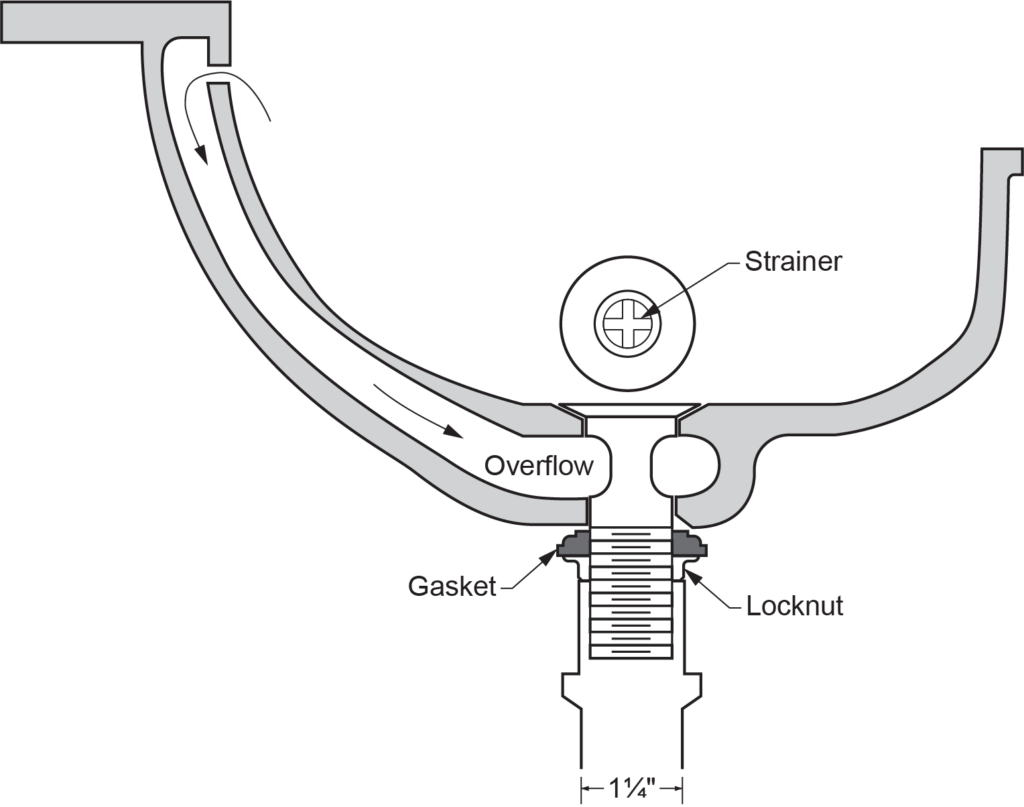

The PO is designed to accept drainage from the basin and overflow (if so equipped). If the basin is filled with water to the inlet of the integral overflow, the PO assembly allows the flow to enter the fixture drain (Figure 50).

The fitting may have an integral strainer and a threaded bottom section that act as a locknut, holding the PO tightly in the drain opening. Lavatories have minimum [latex]1\tfrac{1}{4}[/latex] in. (32 mm) outlet pipes.

Pop-Up Waste

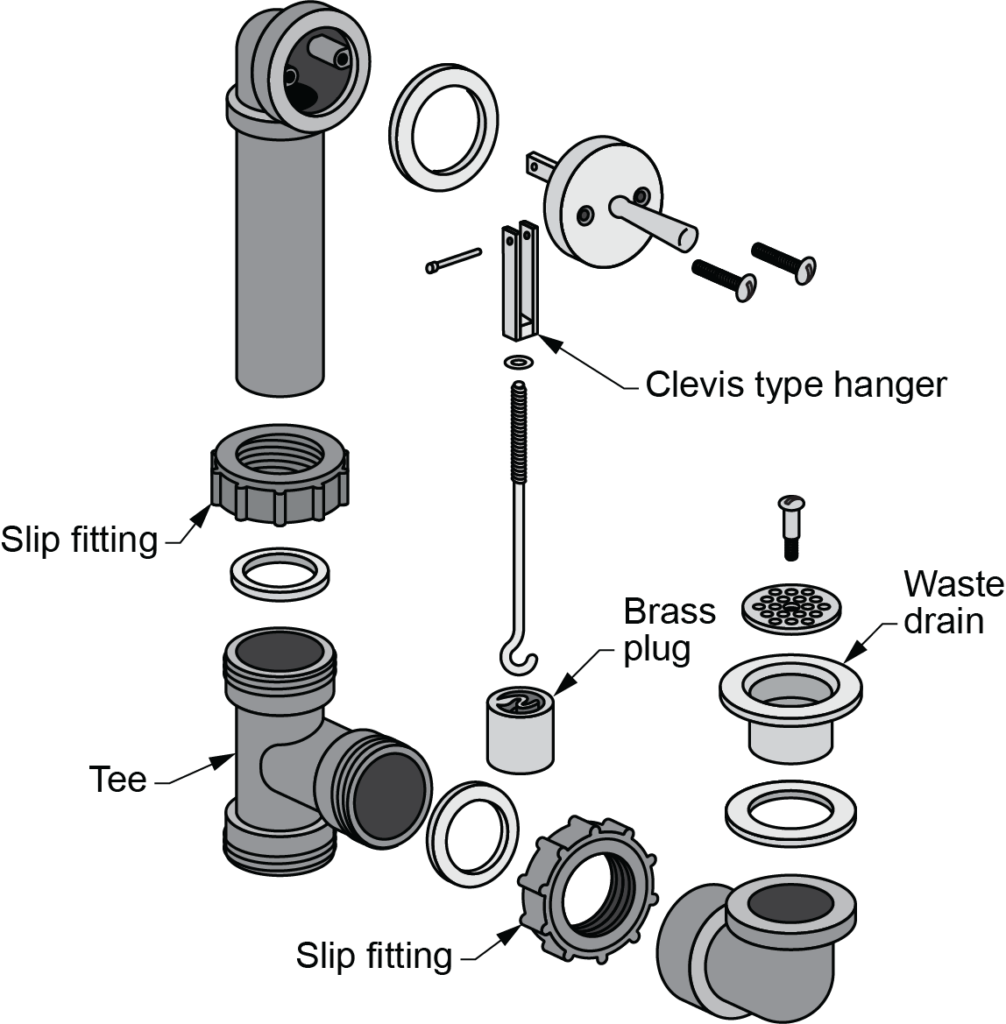

The pop-up waste, sometimes referred to as a mechanical PO (Figure 51), is a common type of basin drain. A simple mechanical linkage pushes a lever or knob on the basin ledge or faucet centrepiece, causing the plug in the drain to lift to allow the basin to drain. Lifting the lever or knob reseats the plug, sealing the basin. Different designs of mechanical linkages are available.

Bathtub Waste and Overflow

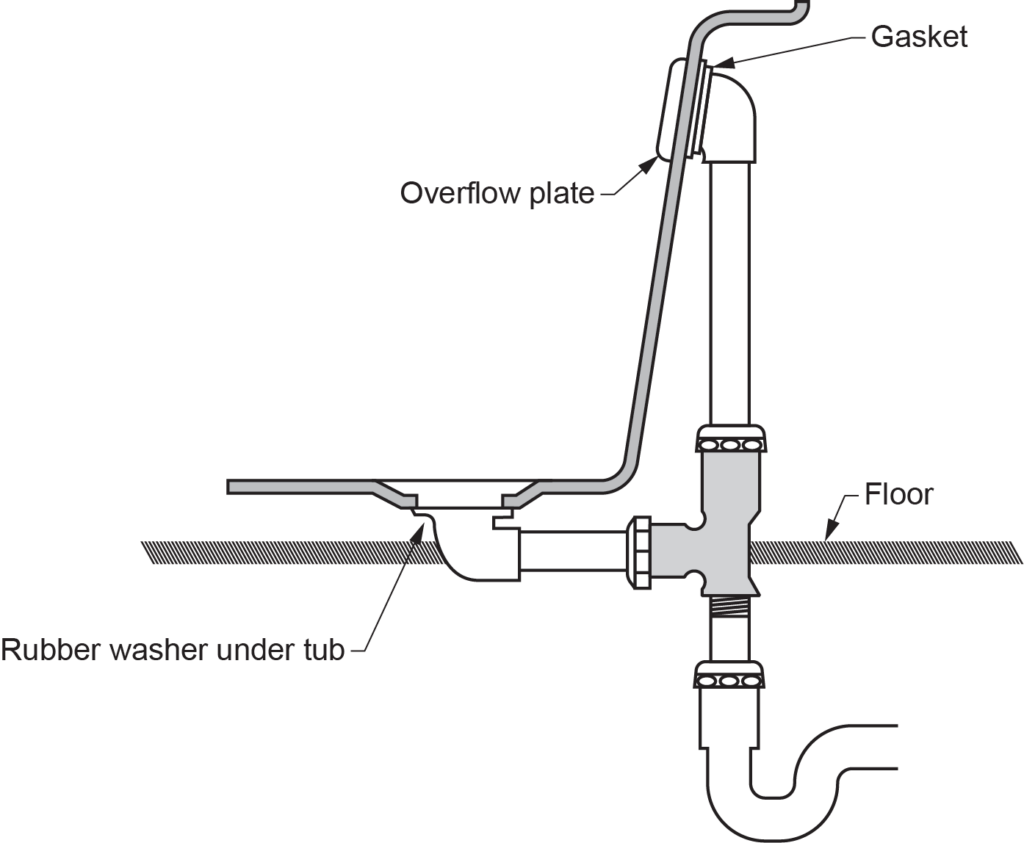

Bathtubs use a waste and overflow fitting to prevent overflowing if the water is left running. The waste and overflow fitting consists of a tee that connects a tube from the overflow plate in the wall of the tub and to the tub drain outlet (Figure 52).

The plug itself may be the older style plug and chain, mechanical stopper, or one of the types of lever and linkage plugs.

Mechanical Stoppers

A common type of stopper fitting is the lift and turn (Figure 53). The fitting attaches to the shaft using a screw threaded into the plug. The screw also acts as a positioning device. The fitting is attached to a pin in the drain that has a flat area on half of the shaft. When the fitting is lifted and turned, the screw sits on a shoulder that keeps it in the open position. Turning the fitting moves the screw off the shoulder and onto the flat area of the pin, allowing the fitting to drop and seal the outlet.

The toe touch or tip-toe drain assembly (Figure 54) is a spring-loaded fitting that can be pushed open or closed with a simple touch. It is a simple arrangement that is quick to operate.

Bathtub Lever Linkages

Common types of mechanical linkages used to raise and lower the bathtub plug are as follows:

- Brass plug

- Rocker arm

- Cable-driven

A brass-plug waste and overflow fitting has a lever mounted on the overflow plate on the tub. The lever lowers or raises a brass plug, which is suspended by a threaded hanger within the overflow tube. When the plug is in place, water cannot enter the downstream drain piping (Figure 55).

A rocker-arm waste and overflow fitting has a linked rocker arm that moves up and down to raise and lower the stopper in the bathtub outlet fitting (Figure 56). A manual lever mounted on the overflow plate also triggers the action of the rocker arm.

Cable-driven styles simply use a cable to activate the drain assembly instead of a linkage. The cable is activated by turning the faceplate located on the overflow cover (Figure 57).

Kitchen Sink Drains

Kitchen sinks have a minimum [latex]1\tfrac{1}{2}[/latex] in. (38 mm) outlet tailpiece that extends from a [latex]3\tfrac{1}{2}[/latex] in. (89 mm) basket-strainer assembly (Figure 57). These assemblies are commonly made of stainless steel or plastic. Basket strainers house a plug mechanism sometimes called a crumb cup.

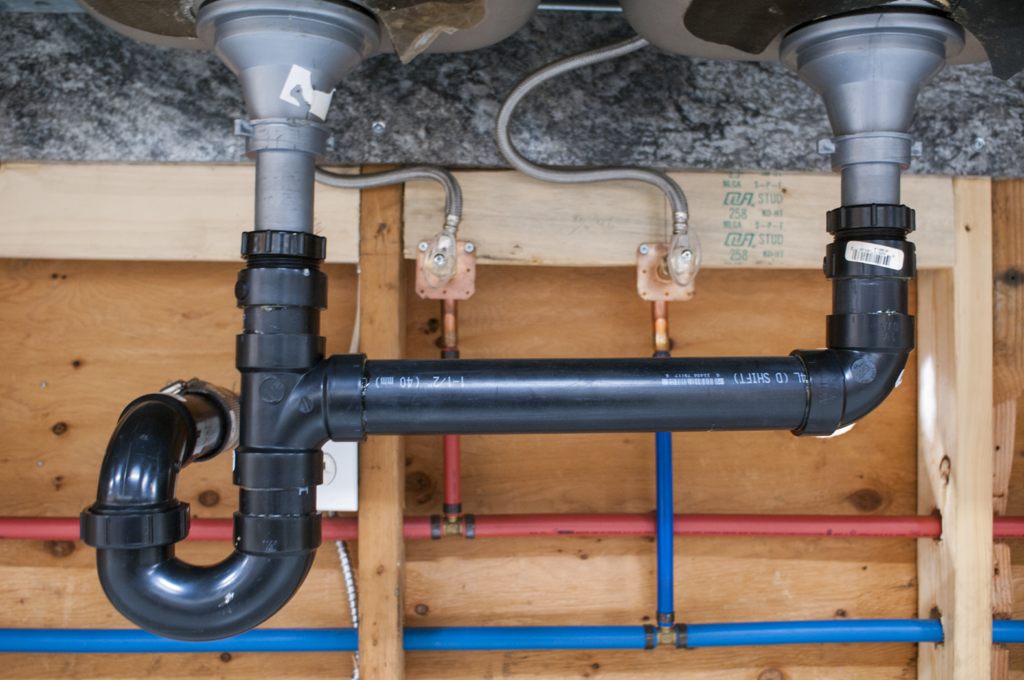

Kitchen sinks may have more than one compartment. In these cases, the drain outlets from each compartment are piped to a common trap with a drainage assembly called a continuous waste (Figure 59). The common trap for multi-section sinks can be a minimum [latex]1\tfrac{1}{2}[/latex] in. (38 mm) for up to two compartments. Three-compartment sinks require a minimum 2 in. (50 mm) common trap.

When dishwasher drainlines are connected to the outlet pipes of an adjacent kitchen sink, the connection must be made upstream of the sink’s trap to avoid the entry of sewer gas into the dishwasher. Dishwasher drain fittings (Figure 60) allow the discharge hose to connect to the outlet piping. The discharge hose from the dishwasher must be fastened under the counter as high as possible to avoid backflow of sewage from the sink into the dishwasher sump in the event of a fixture drain blockage.

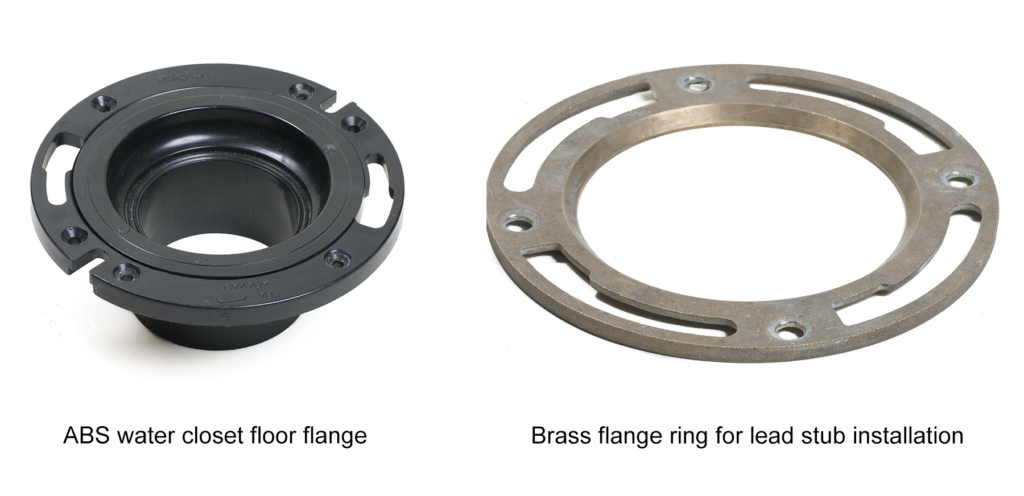

Toilet Flanges

Water-closet floor flanges (Figure 61) are available in ABS, PVC, CPVC, brass, and cast iron. Brass floor flange rings are used when connecting a water closet to a lead stub or bend. Floor flanges and lead fittings act to connect floor outlet toilet bowls to the water closet trap arm and provide a finished mounting of the fixture. Flanges are available in extension fittings and offset patterns to accommodate different installation requirements.

Fixture Stops and Supply Tubes

Fixture stops, also known as shutoff valves (Figure 62), are used as an accessible means to isolate the water supply to a fixture. Installed at the point of use, these valves are commonly used to reduce the supply pipe size from the water distribution system to a smaller connector (supply tube) size. Available in a multitude of connection methods and patterns, they offer a convenient way to service or replace fixtures, such as faucets, sinks, water closets, and dishwashers.

Fixture supply tubes (also known as supply risers, supply connectors, or supply lines) (Figure 63) are permitted by plumbing codes to be used to connect certain fixtures if the maximum length of the connector does not exceed 750 mm (30 in.) and the minimum ID of the tube is at least 6.3 mm ([latex]\tfrac{1}{4}[/latex] in.). These may be commonly referred to as [latex]\tfrac{3}{8}[/latex] in. supply tubes, as their outer diameter (OD) is [latex]\tfrac{3}{8}[/latex] in. (9.5 mm).Figure 62 shows various types of supply connectors. Braided supply lines are a popular choice because they offer the greatest flexibility during installation and do not require the use of tubing ferrules. Copper and chrome-plated supply tubes are usually offset with a [latex]\tfrac{3}{8}[/latex] in. OD tubing bender to accomplish the change in direction required from the supply stop to the fixture.

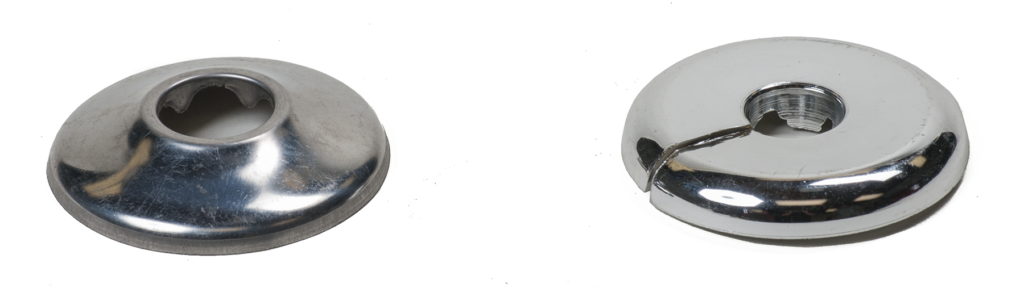

Escutcheons

Wherever piping protrudes through holes in walls, chrome-plated metal or plastic finishing flanges known as escutcheons (Figure 64) should be installed. Some escutcheons have a deeper shell that can be used to cover a coupling or fitting. Some of these flanges are one piece and are intended to be installed during construction, while others are multi-piece and are intended to be installed after the piping system is fully connected. Escutcheons should be sized to the exact outside diameter (OD) of the pipe or tube.

Faucets

Faucets are sometimes commonly known as taps. A faucet supplies hot and cold water for baths, sinks, and lavatories. Older installations once used separate taps (or spigots) for hot and cold supplies. Modern faucets are of the mixing style, where hot and cold water are mixed within the faucet body before being emitted at the spout as a single stream.

Faucets for lavatories and sinks are limited by code to a maximum permitted flow rate of 8.3 L/min (2.1 USGPM). Faucets must comply with the CSA B125 standard for supply fittings. Whenever a faucet’s outlet is provided with a means to attach a hose, such as a janitor’s faucet, the outlet must be protected by the installation of a vacuum breaker to prevent back-siphonage backflow.

There are four basic types of faucet mechanisms:

- Compression

- Cartridge

- Ball

- Ceramic disk

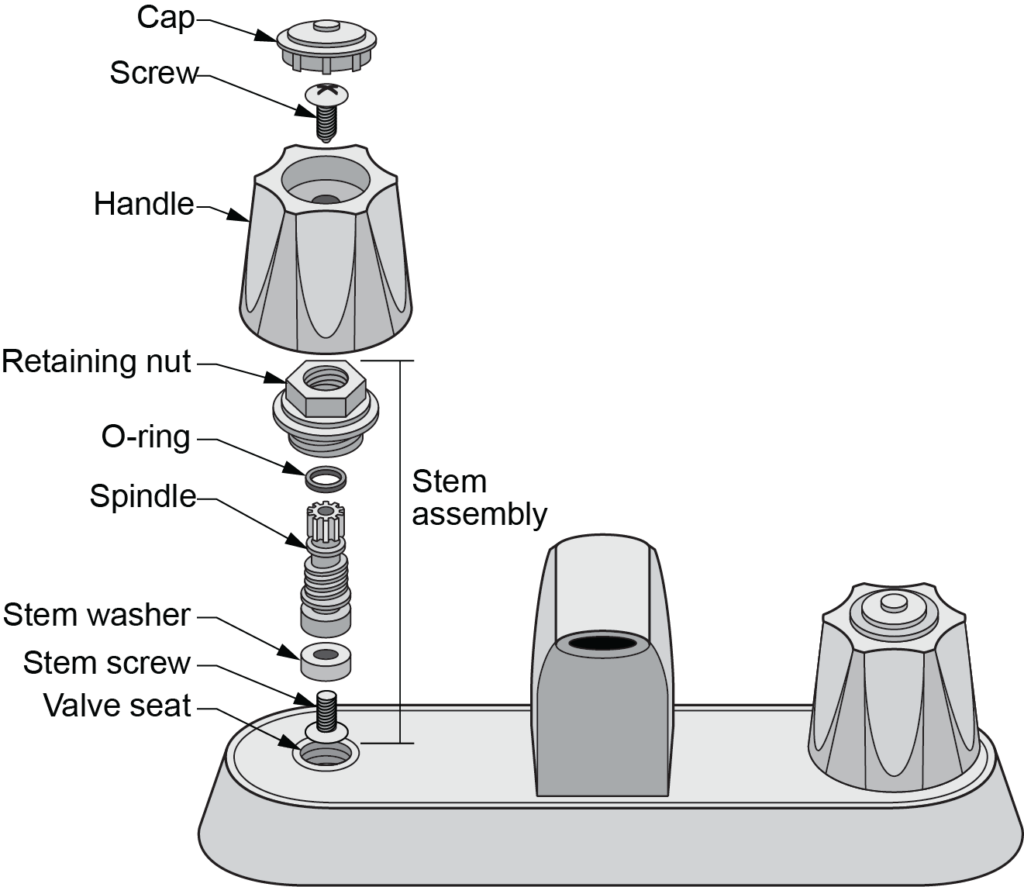

Compression Faucets

Among the various faucet tap technologies in use, two-handled compression-type faucets (Figure 65) that use washers have been around the longest. They are also the least expensive type.

With a compression faucet, the handle is rotated to raise or lower a stem. At the stem’s base, a washer opens or closes the water passageway (the valve disk and seat). The fundamental problem with a compression faucet is that the rubber washer wears out over time. When this happens, the tap drips.

Some newer types of compression faucets lower and raise the washer without grinding it into the valve seat. For example, one faucet is designed to lift and lower the rubber washer vertically without rotating it. Because it does not grind the washer against the seat, the washer tends to last longer.

The remaining three styles are commonly referred to as washerless faucets (although they still utilize O-rings or seals) and are variations on the simple and effective plug- or ball-style supply valve. Water flow is controlled by turning components within the valve until they are aligned with the water flow passageway. The degree of alignment controls the mixture of hot and cold water. Many are of the single-handled variety.

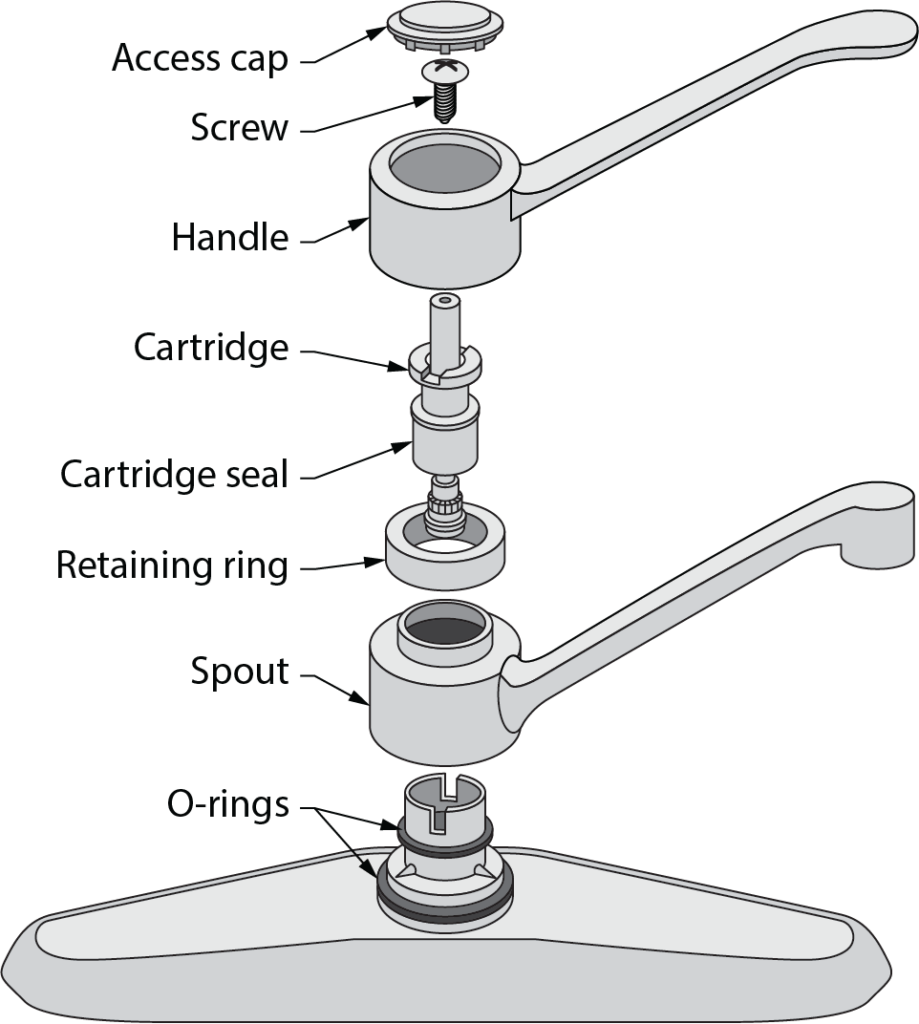

Cartridge Faucets

Cartridge faucets (Figure 66) have a hollow metal or plastic cartridge insert which seals against the spout or faucet body. Depending on how a series of holes in the cartridge align with the stem, water is mixed and controlled. Dripping usually means the cartridge needs replacing.

Cartridge faucets control flow using methods other than a disk washer and valve seat. Water flow is controlled by an up-and-down movement of the cartridge; to change water temperature, rotate the single handle.

These faucets are very reliable; many leaks are generally due to a simple O-ring failure.

Ball Faucets

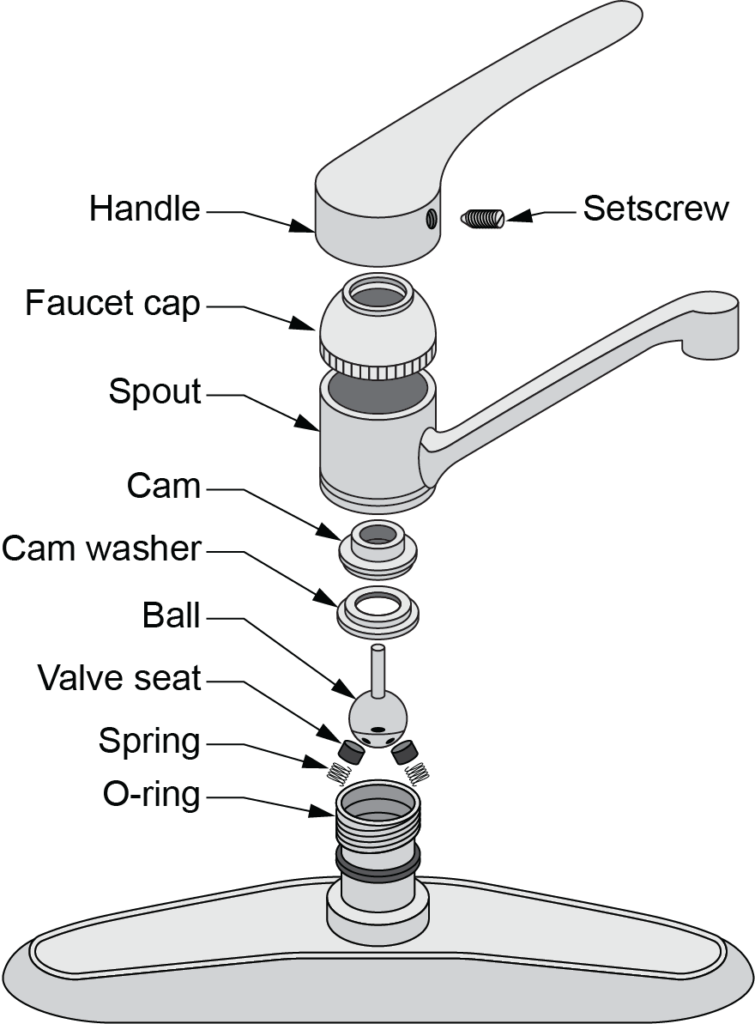

Seat-and-spring (ball-type) faucets have a stainless steel or plastic ball with slots that are turned and aligned with water flow openings in the faucet body (Figure 67). These openings have spring-loaded rubber caps or seats that press against the globe as it rotates to maintain a tight seal.

Ceramic Disk Faucets

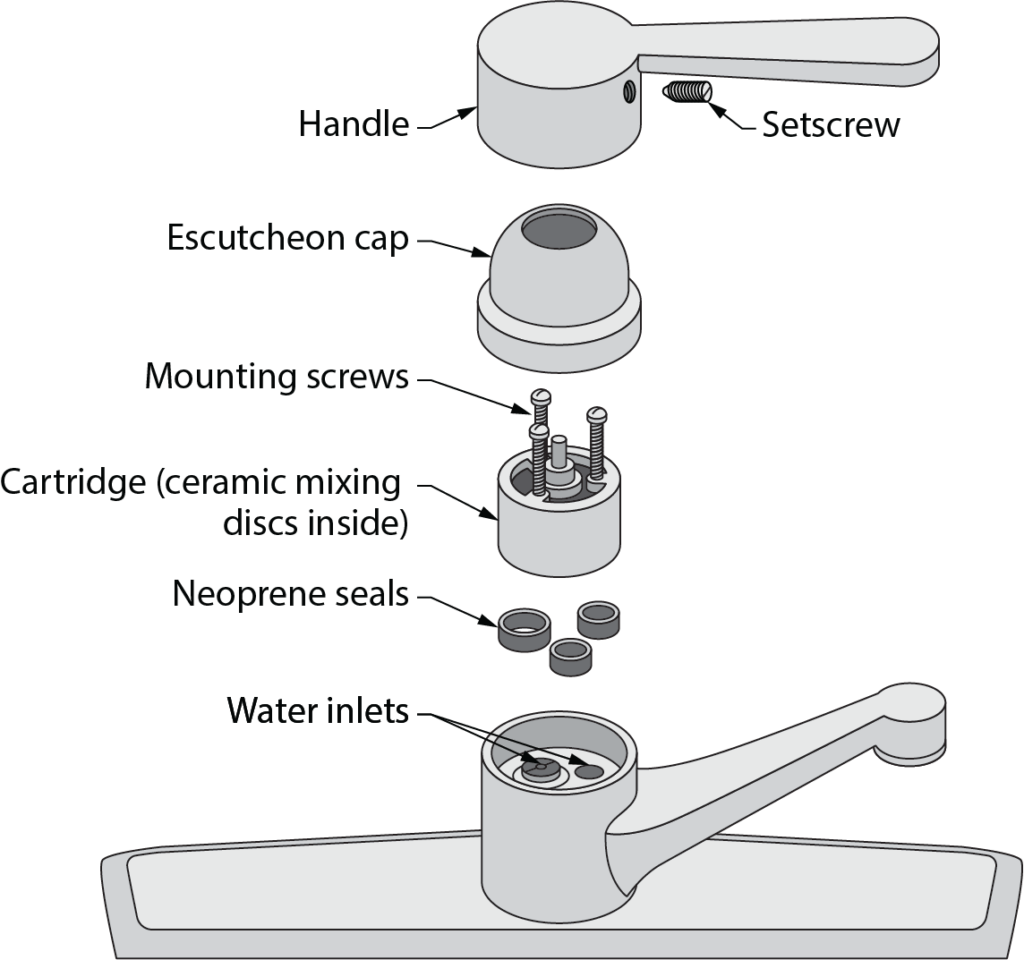

Ceramic disk faucets (Figure 68) have two fire-hardened ceramic disks — an upper one that moves and a fixed lower one. One disk moves against the other in a shearing action, blocking water or allowing it to pass through. The seal between the two disks is watertight because they are polished to a near-perfect flatness. Ceramic disk faucets were first made popular by high-end European faucet makers and are now produced by many North American faucet manufacturers.

Ceramic disk faucets are nearly maintenance-free. Ceramic valves are more durable over a variety of water conditions than any other variety of valve on the market. The disks themselves have diamond-like hardness — they are impervious to line debris, mineral buildup, and other common problems that affect valve life.

Faucet Controls

A single-lever–type faucet has a long handle or lever mounted on the spout. Lifting the lever turns the water on and controls the volume delivered. Moving the lever to the right or left adjusts the mixture of hot and cold water. Most faucet spouts have aerator assemblies, which are a fine mesh screen assembly mounted at the outlet to limit maximum flow and create a soft spray pattern.

Faucet spouts used in bathtubs are referred to as tub fillers (Figure 69). When combined with showers, they are known as combination tub and shower valves; sometimes, the entire rough-in assemblies are generically known as tub diverters. Tub fillers may have separate hot and cold compression-style controls or one single-handled cartridge-style mixing valve and a central spout. Telephone showers (handheld shower units with a hose attachment) can be connected to the spout of a tub filler unit or be integrated into the shower head outlet.

Combination tub and shower valves commonly use a central mixing valve that controls the flow volume and temperature to the shower or to fill the bathtub. The actual diverter valve is controlled by a lift rod installed on the tub spout (Figure 69) or by some other means. When the diverter valve is held in position, water flow is forced up through the shower riser and shower head instead of out the tub spout.

Shower head flow rates are limited by code to a maximum permitted flow rate of 9.5 L/min (2.5 USGPM). Codes also require that valves that supply fixed-location shower heads be either of the pressure-balanced or thermostatically controlled type. The maximum outlet temperature to a bath tub or shower head shall not exceed 49°C (120°F).

Sensor-Activated Controls

Sensor-controlled faucets (also known as hands-free, automatic, touchless, motion-sensor, or infrared faucets) (Figure 70) are faucets equipped with a proximity sensor and mechanism that opens its valve to allow water to flow in response to the presence of a hand or hands. The faucet closes its valve again after a few seconds or when it no longer detects the presence of hands. Most automatic faucets are battery-powered and incorporate an active infrared sensor to detect hand motion. Some are hard-wired and some have solar cells that can power the valve from any light source. Automatic faucets are common in public washrooms, particularly in airports and hotels, where they help to reduce water consumption and reduce the transmission of disease-causing microbes. They can also be found in some kitchens and washrooms of some private residences.

Automatic faucets were first developed in the 1950s but were not produced for commercial use until the late 1980s, when they first appeared to the general public at airport lavatories. It is estimated that sensor-controlled faucets can reduce typical lavatory water consumption by as much as 70%.

Automatic faucets have the advantage of shutting off automatically after handwashing, thereby reducing water waste. They can also benefit the elderly and those suffering from arthritis or other mobility-limiting conditions since there are no handles to twist or pull. Their automatic shutoff mechanism also greatly reduces the risk of sink overflow due to a faucet being left on either inadvertently or deliberately.

Automatic sensor controls are also used frequently in commercial installations of urinals and water closets that use direct-flush valves (Figure 71). Even residential hands-free options are now available, like foot-activated flush kits. Retrofit sensors are also on the market, even for flush tanks.

Sensor-activated water-closet motorized flush valves were first widely introduced commercially in the mid 1970s, but they were much more elaborate devices than the compact units installed today.Because water closets and urinals have a fixed cycle when they operate, automatic sensors are used mainly to avoid spreading microorganisms by eliminating the need to touch the controls. Many users experience problems when using these fixtures if the sensors are not set up correctly.

Pressure-Balanced and Thermostatic Control Valves

Single-control pressure-balanced valves (Figure 72) sense the proportion of cold and hot water as the user turns the handle. The pressure balance valve does not sense the actual temperature of the water, just the ratio of hot and cold water supplied to the valve. When a toilet is flushed or another fixture is used while someone is showering, an internal cartridge automatically balances hot and cold water pressures to prevent shock to the bather. Each time the valve is turned on, full flow is provided to the shower head or tub, but users must select the temperature of the shower each time it is used. A mechanical limit stop restricts the travel of the control lever to set the maximum temperature delivered to 49°C (120°F).

Thermostatic valves (Figure 73) have two handles: one controls the mix of hot and cold and the other controls on/off and the volume of water passing through the valve. The mixing valve in the thermostatic valve senses the actual temperature of the water and constantly adjusts the mix to maintain the temperature selected. It is not necessary to turn the mix handle to turn the water off or on. Once the bather selects a temperature, the valve will automatically go to that temperature again when the water is next turned on.

Thermostatically-controlled water valves are commonly specified for installation in many schools, hospitals, recreation centres, and industrial workplaces. They are also used in quality residential tub and shower valves. Digital thermostatic valves are available that allow the user to preset water, steam, lighting, and music through an intuitive interface.A common design uses a liquid-filled expansion-type thermostat (housed within the valve assembly) to measure the temperature and mix the hot and cold water supply to achieve the selected delivery temperature. Usually, you turn a single handle or dial to select a general temperature range. The actual temperature range that will be achieved by turning the handle or dial is preset. The valve assembly includes a concealed adjustment for raising or lowering this range. The anti-scald safety feature built into the valve design ensures that water will automatically shut off whenever the cold water supply drops below a certain level or stops. This prevents any chance of scalding or burns from hot water.

Fountain Bubblers and Controls

Bubblers are the supply fitting used to deliver water in drinking fountains. The name bubbler may derive from the fact that the water is supplied with a slow head or delivery pressure that makes it appear to be bubbling from the fixture. Different designs are available, but all feature a protective hood or shield on one side of the outlet (Figure 74) and a raised spout to deliver the water above the flood level of the water fountain base. The water delivered from a fountain bubbler must be directed upward at an angle of approximately 45° to prevent contamination from the user’s mouth.

Different types of bubbler controls are available. Some use a push button to open and close the supply valve. Another control type is a self-closing rotating stop that has a metal or plastic handle. The water is turned on only when the knob is held open by hand. As soon as the knob is released, the valve closes.

Drinking fountains must have a means to regulate flow from the orifice to an acceptable delivery rate. Automatic flow regulators (Figure 75) maintain constant stream heights under fluctuating line pressures. Most are [latex]\tfrac{1}{4}[/latex] NPT threads or a push-type fitting. Some fountains have the flow regulator built into the push button–style cartridge.

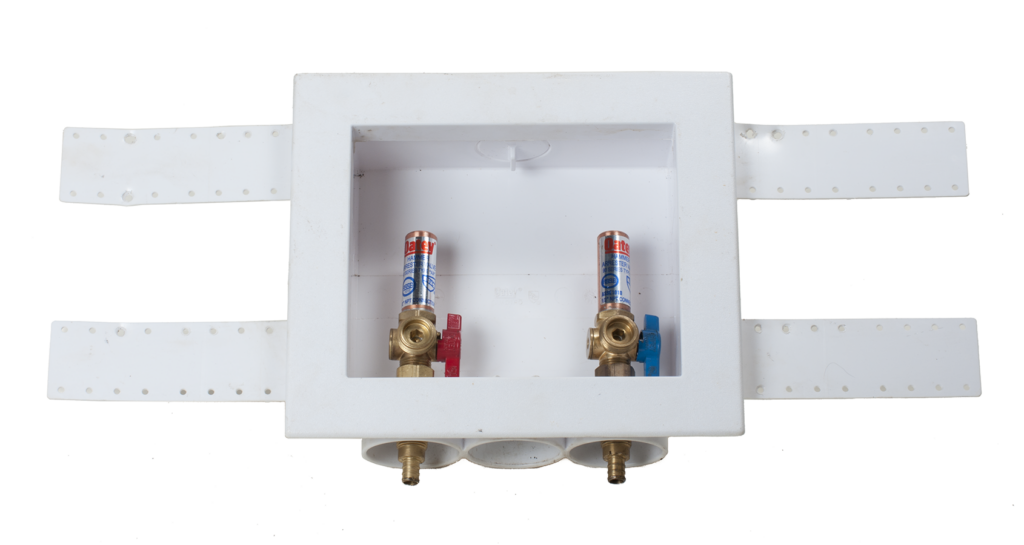

Laundry Boxes

Laundry boxes (Figure 76) supply a set of hot and cold hose bibbs, often a 2 in. (50 mm) NPS drain connection for the laundry standpipe, and are available with built-in water hammer arrestors. Laundry boxes enable the standpipe and water lines to be concealed, providing a clean look to the installation. The clothes washer hoses are connected to the hot and cold supplies and the discharge line is placed into the drain inlet of the box.

Carrier Fittings and Brackets

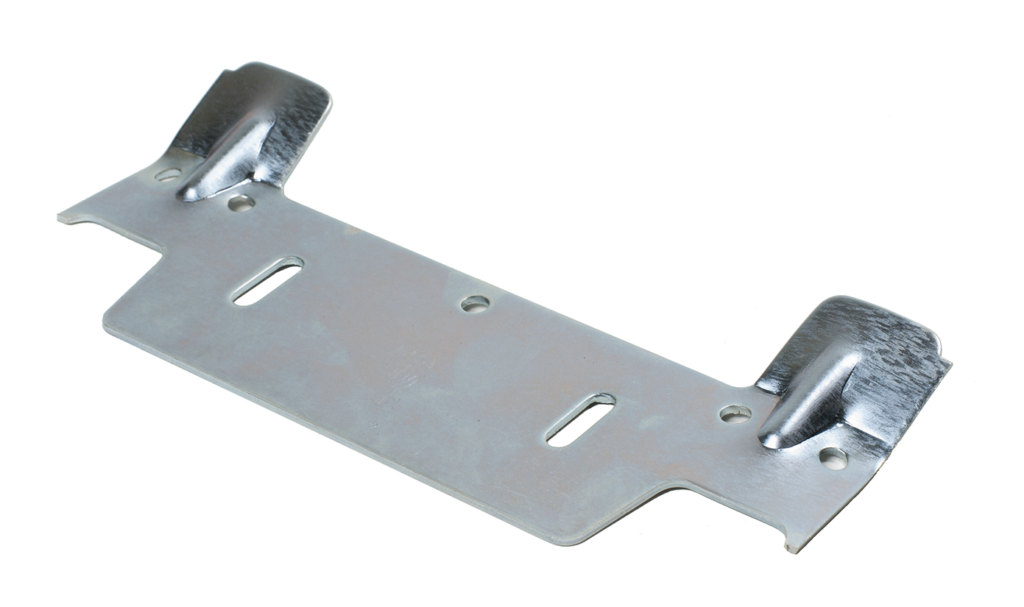

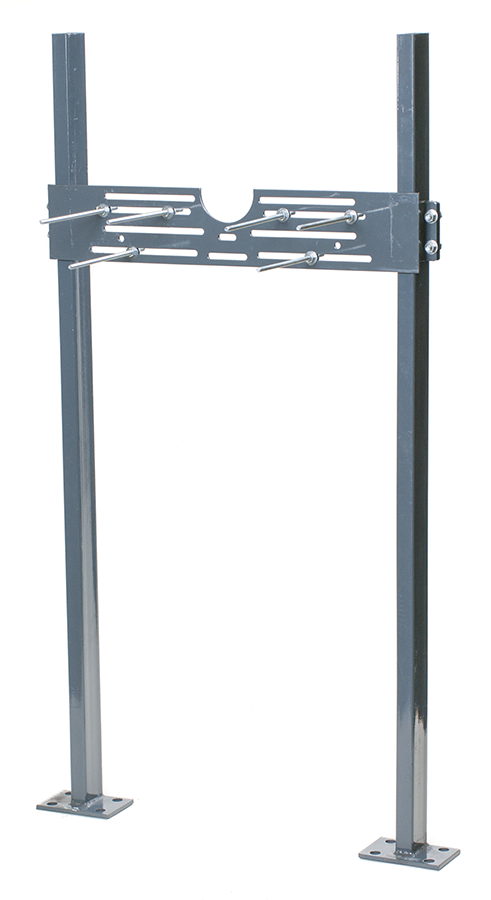

Available for commercial, institutional, and some residential lavatories, water closets, and urinals, concealed wall carriers provide increased strength for supporting a fixture. These steel carriers have arms, brackets, and attachment points that allow the fixture to be wall-mounted without strain or damage to the wall finish.

Wall-mounted fixtures require a sound base that can be anchored to a structural component. In wood-frame construction, carrier fittings and mounting brackets can be attached to studs in the wall (Figure 77).

Commercial projects often require that the carriers and supports be freestanding in the wall cavity and fastened to the structural floor (Figure 78).

Water-closet carriers must support the weight of the wall-mounted bowl plus the full weight of the user without transferring any weight to the wall or piping. Closet carriers are often installed in batteries to accommodate multiple fixtures and may also be installed for back-to-back installation. Substantial provisions must be made for these types of fixtures when roughing in the drainage and venting system.

Wall-mounted water closets are mounted with either a four-bolt (siphon jet) or three-bolt (blowout) pattern. When ordering single carriers for horizontal connections (Figure 79), you must specify direction of flow. Determine direction of flow as if you were sitting on the fixture, facing away from the wall. Back-to-back carriers are reversible and do not require a flow direction specification.

Carriers have adjustable threaded rods and threaded drain nipples to accommodate various wall thicknesses and finishes.

Barrier-Free/Universal Design Requirements

The presence and participation of people with disabilities in our communities is significant. The percentage of people with disabilities of all ages will increase, especially over the next few decades, with each type having their own specific design needs. Barrier-free or accessible in this context means that a person with disabilities can approach, enter, exit, operate, participate in, pass to and from, and make use of a building’s facilities without assistance.

When referring to building code, specifically the sections dealing with building requirements for people with disabilities, plumbers must be aware of the strong impact that proper application of the code has on the day-to-day lives of people with disabilities.

The BC Building Code Section 3.8 of Division B, “Accessibility,” comprises a large portion of the requirements of the code dealing with access for persons with disabilities, but there are requirements contained elsewhere in the code that also pertain to accessibility. Some of these requirements are design specifications for specific facilities, such as washrooms, which are contained in Section 3.7 of Division B, Health Requirements. Other items originated as requirements for persons with disabilities but have become universal requirements applicable to all building users, not just those with disabilities.

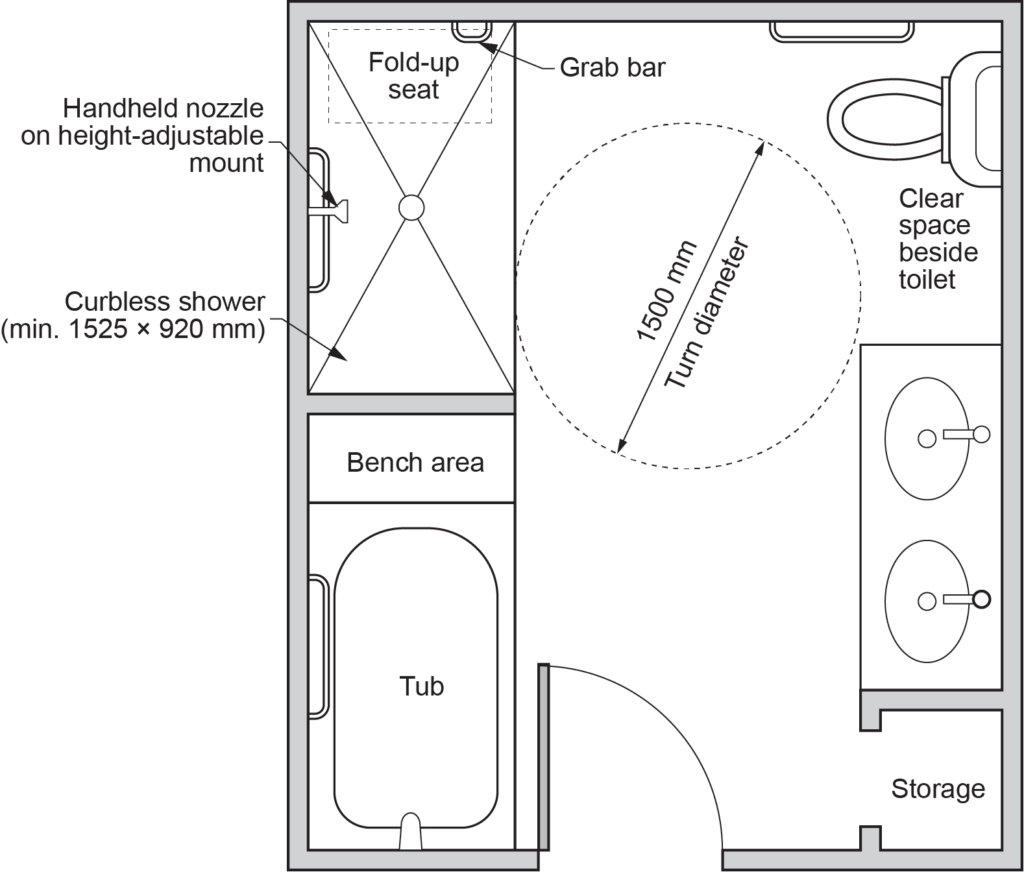

Requirements for a minimum turning radius for wheelchairs and clearances from obstructions are examples of good design (Figures 80 and 81). Always consult with job specifications to ensure that minimum code and specifications are being met.

Bathroom design has become increasingly sensitive and responsive to the needs not only of the physically challenged but also of an aging population. Universal design, while incorporating the spirit and some features of accessible design, has a broader scope. Universal design intends to create an environment that functions appropriately for all, regardless of physical capacity. This would include, for example, people with arthritic conditions; the elderly, injured or movement-impaired; and small children. Creating a bathroom environment that allows people of all ages and physical capacities to use the facilities safely and with ease is the motivating force behind universal design.

Gender-neutral washroom facilities are also increasingly common in public buildings and can be used by any person, regardless of gender identity.

A universal design bathroom incorporates and extends many of the features of an accessible design bathroom but focuses on users who are aging rather than disabled. Universal design relies on common sense and strives to be user-friendly for anyone who uses the bathroom.

Universal design principles focus on:

- Ease of use

- Easy access

- Adjustability

- Safety and stability

Ergonomic wing-blade faucet handles or motion-sensor taps, for example, aid those with arthritis who have difficulty turning bathroom handles. A tub’s faucet set placed on the outer rim of the bathtub makes it easier to reach for someone who has difficulty bending or is prone to dizziness. Adjustable-height handheld shower heads allow a shower to be customized for the tallest to the smallest. Built-in or installed seating in the bathtub or shower offers that option to those who cannot stand for extended periods. Grab bars placed strategically around the toilet and outside and inside the tub or shower not only help the frail and movement impaired but also provide an extra measure of stability in the bathroom to children and able-bodied adults.

Other universal design bathroom safety features, such as anti-scald devices on all faucets, shatterproof materials, and slip-resistant flooring, make the bathroom safer for everyone.

Self-Test C-1.1: Types of Fixtures and Trim

Self-Test C-1.1: Types of Fixtures and Trim

Complete the Self-Test C-1.1 and check your answers.

If you are using a printed copy, please find Self-Test C-1.1 and Answer Key at the end of this section. If you prefer, you can scan the QR code with your digital device to go directly to the interactive Self-Test.

References

MAAX. (n.d.). Essence TS 6030 Afr Acrylic Alcove Four-Piece Tub Shower [Product image]. MAAX. Retrieved March 21, 2025, from https://maax.ca/product/essence-ts-6030-afr-acrylx-alcove-four-piece-tub-shower/148007/148007-l-000-002. [MAAX Canada is a subsidiary of ABG American Bath Group.]

MAAX. (n.d.). B3Square 4836 Acrylic Configurable Shower Base [Product image]. MAAX. Retrieved March 21, 2025, from https://maax.com/product/b3square-4836-acrylic-configurable-shower-base/420003/420003-504-001. [MAAX Canada is a subsidiary of ABG American Bath Group.]

Skilled Trades BC. (2021). Book 2: Install fixtures and appliances, install sanitary and storm drainage systems. Plumber apprenticeship program level 2 book 2 (Harmonized). Crown Publications: King’s Printer for British Columbia.

TOTO USA. (n.d.). Corporate information. TOTO USA. Retrieved March 21, 2025, from https://www.toto.com/en/corporate/

TOTO USA. (n.d.). Prominence® Pedestal Lavatory [Product image]. Retrieved from https://www.totousa.com/prominence-pedestal-lavatory-1?color=cotton

Trades Training BC. (2021). C-1: Install fixtures and trim. In: Plumber Apprenticeship Program: Level 2. Industry Training Authority, BC.

Media Attributions

All figures are used with permission from Skilled Trades BC (2021) unless otherwise noted.

- Figure 2 Prominence® Pedestal Lavatory (SKU: LPT242G#01) is from TOTO USA (n.d.), and is used with permission.

- Figure 3 Enameled bathtub by ErikaWittlieb on Pixabay

- Figure 4 Hand-hammered copper tub [modified] is by Dora Smith on Flickr, and used under a CC BY-NC 2.0 license.

- Figure 5 Pink bathroom suite, Skaill House, Orkney [cropped – “Acrylic Tub”] by Mike Shaw, via Wikimedia Commons, is used under a CC BY SA 4.0 license.

- Figure 6 Black Wooden Sink Cabinet with Mirror (Marble basin) by Andrea Davis, via Pexels is used under the Pexels License.

- Figure 8 Commode (Floor-mounted, bottom outlet, close-coupled, tank-type water closet or toilet). by Rosalie Boucher on FreePNGimg.com is used under a CC BY-NC 4.0 license.

- Figure 9 Old toilet with elevated cistern and chain (Floor-mounted, bottom outlet, high tank water closet) is by Gregorydavid at English Wikipedia and is used under a CC BY-SA 3.0 license.

- Figure 10 Floor -mounted, bottom outlet, direct-flush water closet is from Toto, USA and it is used with permission.

- Figure 13 Siphon jet water closet by SouthHamsian, via Wikimedia Commons, is used under a CC BY-SA 4.0 license.

- Figure 14 (left) vacuum assist water closet filling; (right) vacuum assist water closet flushing, from Fine Homebuilding® (2010) is used with permission.

- Figure 20 Wall-hung urinal with direct-flush valve is from Toto, USA and it is used with permission.

- Figure 23 Stainless steel trough urinal by Daniel Lobo, via Flickr, is in the public domain.

- Figures 24-26 Lavatories are from Toto, USA and are used with permission.

- Figure 27 Countertop lavatory for hair salon [modified], by Michelle Raponi, on Pixabay is used under the Pixabay License.

- Figure 29 Double compartment stainless steel kitchen sink by Brett Hondow on Pixabay is used under the Pixabay License.

- Figure 33 Recessed bathtub with surround from MAAX Canada (n.d.), is used with permission. MAAX Canada is a subsidiary of ABG American Bath Group.

- Figure 34 Freestanding clawfoot tub by lifeforstock on Freepik is used under the Freepik License.

- Figure 35 Whirlpool tub by jingdianjiaju2, on Flickr is used under a CC BY-SA 2.0 license.

- Figure 36 Standard shower base from MAAX Canada (n.d.), is used with permission. MAAX Canada is a subsidiary of ABG American Bath Group.

- Figure 38 Bidet is from Toto, USA and it is used with permission.

- Figure 46 Hospital autopsy table by Ralf Roletschek, via Wikimedia Commons, is used under a CC BY-NC-ND 3.0 license.

- Figure 47 Stainless steel one-piece prison washroom unit by Édouard Hue, via Wikimedia Commons is used under a CC BY-SA 3.0 license.

- Figure 54 Toe touch from Danco (n.d.) is used with permission.

- Figure 71 Sensor-activated direct-flush water closet is from Toto, USA and it is used with permission.

- Figure 73 Thermostatic control valve is from Toto, USA and it is used with permission.

- Figure 76 Washing Machine Outlet Box is from Oatey Co. (n.d.) and is used with permission.

When metals slowly get damaged or worn away because of reactions with air, water, or other substances. A common example is rust forming on iron when it gets wet. (Section C-1.1)

Also known as vitreous china; a type of very strong and smooth ceramic material made by heating special clay at a very high temperature. This process makes it hard, waterproof, and glass-like, so it doesn’t absorb water and is very durable. It is often used for making sinks, toilets, and tiles. (Section C-1.1)

A strong material made by mixing crushed natural stone with glue or resin. It looks like real stone but is made in factories and is often used for countertops, floors, and walls. (Section C-1.1)

A type of toilet where the tank and the bowl are joined closely together as one unit. The water tank sits right on top of the bowl, making it compact and easy to install. (Section C-1.1)

A special valve used in public bathrooms instead of a regular toilet tank. It releases a strong burst of water to flush the toilet or urinal quickly and refills right away, so it can be used often without waiting. Direct-flush valves are a “tankless” design that uses water pressure from the supply line rather than a tank of water to flush the fixture (Figure 10, Section C-1.1)

Toilets that use less water to flush but still work just as well as regular toilets. They help save water and lower water bills. (Section C-1.1)

Water that forms when warm air touches a cold surface, like the water droplets on a cold drink. In buildings, this water comes from air conditioners, refrigerators, or pipes and is usually drained away as waste. (Section C-1.1)

Water that has been used before and cleaned so it can be used again for things like watering plants, flushing toilets, or washing streets. It is not for drinking, but it helps save fresh water. (Section C-1.1)

Used water from sinks, showers, bathtubs, and washing machines. It is not dirty like toilet water and can sometimes be cleaned and reused for things like watering plants or flushing toilets. (Section C-1.1)

A part of a toilet that helps flush water quickly and powerfully. It pushes water through a small opening to create suction, which helps remove waste from the bowl. (Section C-1.1)

The curved pipe at the bottom of a toilet or sink that helps carry away water and waste. It also keeps a little bit of water inside to stop bad smells from coming back up. (Section C-1.1)

The top edge of the water inside a toilet or sink drain trap (the trapway's highest point). It helps control the flow of water and keeps some water in the trap to block bad smells from coming back up. (Section C-1.1)

A system in some toilets that helps the flush work more powerfully. It uses air pressure to help pull the waste and water down the drain quickly, using less water. (Section C-1.1)

A special type of plumbing pipe that helps prevent bad smells or gases from coming back into a building. It works by trapping a small amount of water in the pipe, but instead of the water being higher, like in a regular trap, it's lower. This helps keep the pipes clear and stops odors from escaping. (Section C-1.1)

A toilet system that uses compressed air to create a stronger flush. As the tank refills, a vessel captures and compresses air, which helps push the water into the bowl more quickly. This results in a more powerful and efficient flush, using less water while improving cleaning performance. (Section C-1.1)

(Also known as supply risers, supply connectors or supply lines); The flexible pipes that bring water from the main water supply to a plumbing fixture, like a sink, toilet, or shower. They connect the fixture to the water lines, allowing water to flow in and out. These tubes are usually made of materials like copper, stainless steel, or plastic, and they are designed to be easy to install and connect to the fixture. (Section C-1.1)

A decorative cover or plate used in plumbing to hide gaps or holes around pipes, faucets, or other fixtures. It helps make the area look neat and clean by covering the space where a pipe or fixture meets the wall or surface. Escutcheons are often used in sinks, showers, and toilets to improve the appearance and prevent water from leaking behind the fixture. (Section C-1.1)

A type of faucet that works by turning the handles to press down on washers inside the faucet. This creates a seal that stops the water from flowing. When you turn the handle, it lifts the washer to allow water to flow, and when you turn it back, the washer closes to stop the water. These faucets are commonly found in older sinks. (Section C-1.1)

A type of faucet that control the flow of water using a cartridge inside. The cartridge is a small, replaceable part that moves to let water flow in or out when you turn the handle. These faucets are easy to use and can help control both the temperature and the amount of water that comes out. (Section C-1.1)

The initial stage of plumbing installation before walls and floors are finished. (Section C-1.1)